IoT and AI have already shown great promise in predictive maintenance and are set to become one of the highest impact technologies for production companies in the future.

Although Smart Factory and Industry 4.0 have been on the billboard for many years, many companies are struggling to quantify what this means for them and what direction to take so that they are not left behind.

There is much confusion as to what IoT and Al provide as it is a difficult topic to understand. Talking to individuals about the implications of IoT and Al in a practical setting is often met with one of two responses: an “a ha” moment or a debate that Al cannot simply solve everything. They are right-Al cannot solve everything; however, it can solve many problems-especially when it is combined with both IoT and a clear goal of increasing production reliability. Before explaining how IoT and Al can achieve this, I will illustrate why companies research predictive maintenance in the first place.

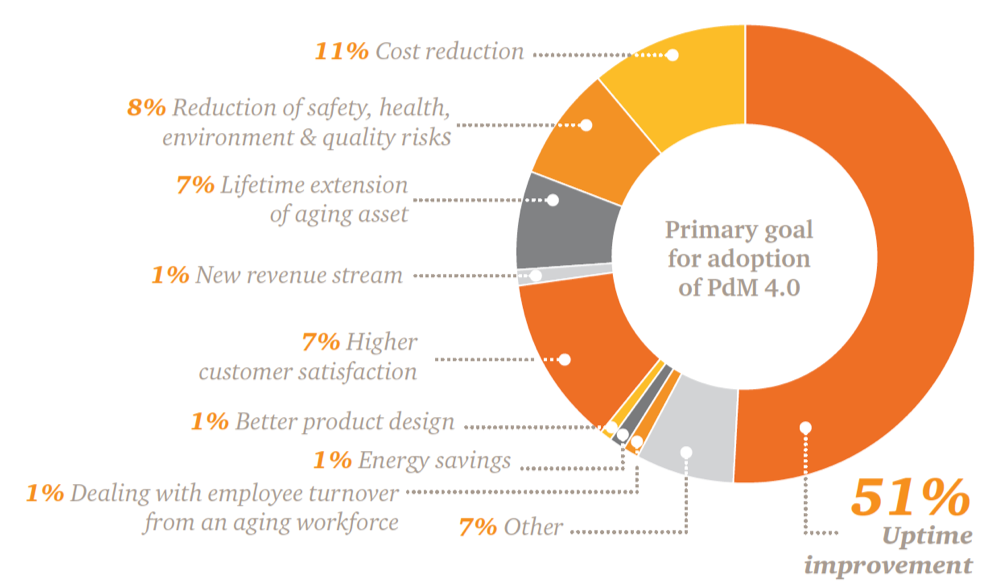

Main motivators for implementing predictive maintenance

One of the significant motivators to implement predictive maintenance is ‘uptime improvement’, which begins to make sense when the return on investment is calculated, as detailed by the illustration below.

Image source: PWC report 2018: Predictive Maintenance 4.0, Beyond the hype: PdM 4.0 delivers results

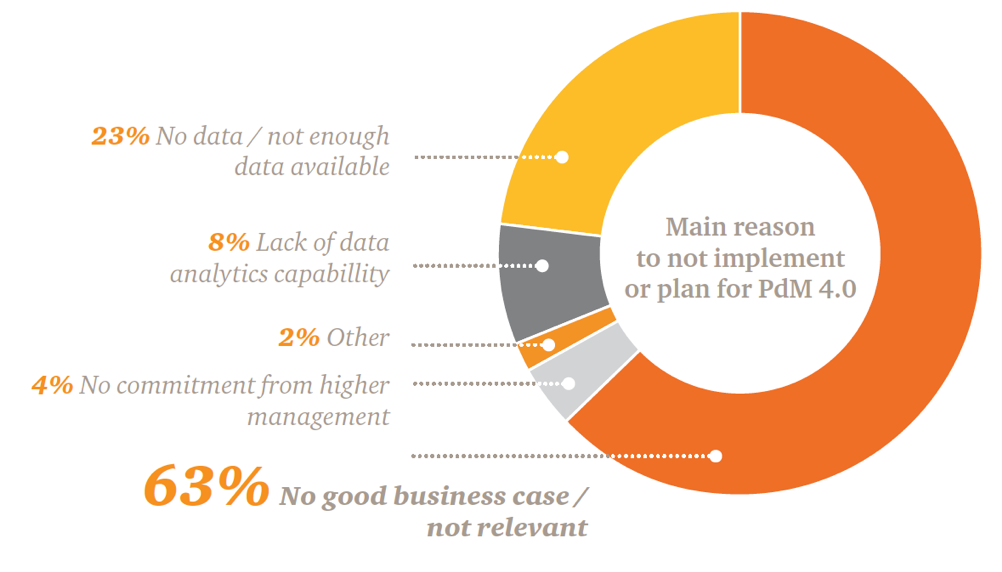

A large number of companies do not see any good business case

According to studies, 63% of businesses do not think that there is a good business case for the need for IoT and Al or that it is relevant for their production. Some 23 % don’t have enough data nor analytical expertise to carry out the implementation. In the illustration below it shows the main reasons for not implementing or plan for PdM 4.0.

Image source: PWC report 2018: Predictive Maintenance 4.0, Beyond the hype: PdM 4.0 delivers results

So, although companies want improved uptime, they do not have enough data available or do not see a valuable argument for the implementation.

Why is there no good business case?

In order to make a strong business case for predictive maintenance the following is needed:

1) Data – and to make sure that you get enough data;

2) You need trained individuals with the skills needed to collect the data.

Therefore, there may be a lack of skillset within the 63% of companies who do not see a case for predictive maintenance

Can this be solved?

Yes, we believe so.

Can it be solved easily?

Yes, we believe so.

How?

Through IoT and AI.

Why is IoT and AI the answer?

Firstly, let’s address the elephant in the room. Let’s talk about AI in predictive maintenance.

Al is unknown to many but has the capacity to solve many problems. However, it can be difficult to understand what it should solve and how it should be solved.

At Hexastate we use AI to quantify the health of a machine. By quantifying the health of a machine, it becomes possible to locate anomalies by developing algorithms. This is fairly simple. Many systems used today give an orange or red alarm, but without understanding the reason for the alarm it becomes difficult to act upon it. Consequently, the challenge is to understand the meaning of these anomalies. Thus, the need arises for vibration experts to understand the alarms or Al.

The AI-driver becomes possible due to accurate high precision sensors and automated analytical software that can interpret data. By using existing research to improve the algorithm’s data interpretation, it becomes possible to understand the anomalies and give practical, instant feedback to the end-user in the field.

Developing these algorithms can take thousands of hours through a trial and error process. Using algorithms, it becomes possible to act as a vibration expert without becoming one yourself.

Should companies start developing these algorithms themselves?

In most cases, the answer would be no due to the fact that it is a lot of work and a significant amount of money needs to be invested in it. The best solution for most companies is purchasing off the shelf specialized products and services instead of developing AI within the company.

In some cases, specialized, off the shelf products and services are expensive. Perhaps this is the reason that 63 % think that there is no business case for predictive maintenance. However, when it comes to machine health in 2020, these companies are somewhat wrong.

Most predictive maintenance solutions have previously only been aimed at companies with highly critical machinery. Many suppliers still focus on this, but as hardware prices dropped and wireless technologies improved it has become possible to develop cheaper solutions to fit Industry 4.0. As a result, IoT is experiencing high growth. It is now possible to develop cheap high precision sensors with multiple-year battery life and a long wireless range using Bluetooth Low Energy, Zigbee, or LoRaWAN.

Combining the cheaper IoT hardware with Al will make all the difference when trying to interpret the data. Fully automated analytical software can help diagnose problems in the machine. In addition, this data will allow companies to implement predictive maintenance tools without needing specialized analytical skills. IoT and Al make the process fully automated. Consequently, businesses will be better able to develop their products in an effortless manner.

This is why IoT and AI will be the driver for predictive maintenance in the future.

Thank you for your time, and if you want to know more about what we work on at Hexastate, please do not hesitate to contact us.