Automated Health

Predict when your machine will break down up to 3 months in advance, and avoid costly downtime.

What is Hexastate Automated health?

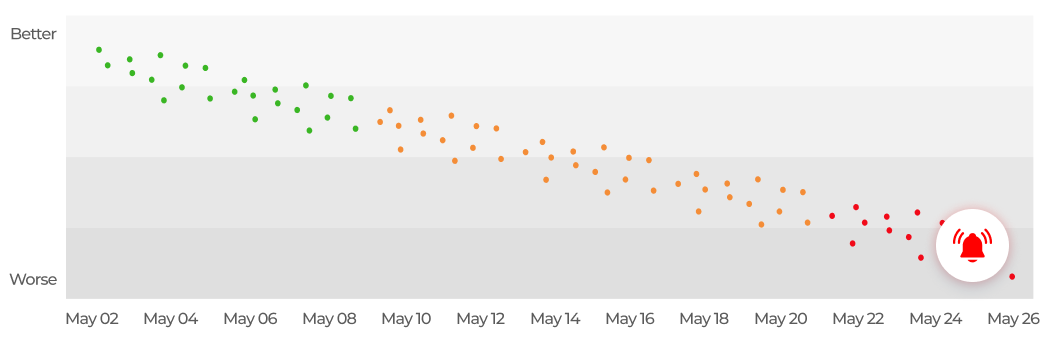

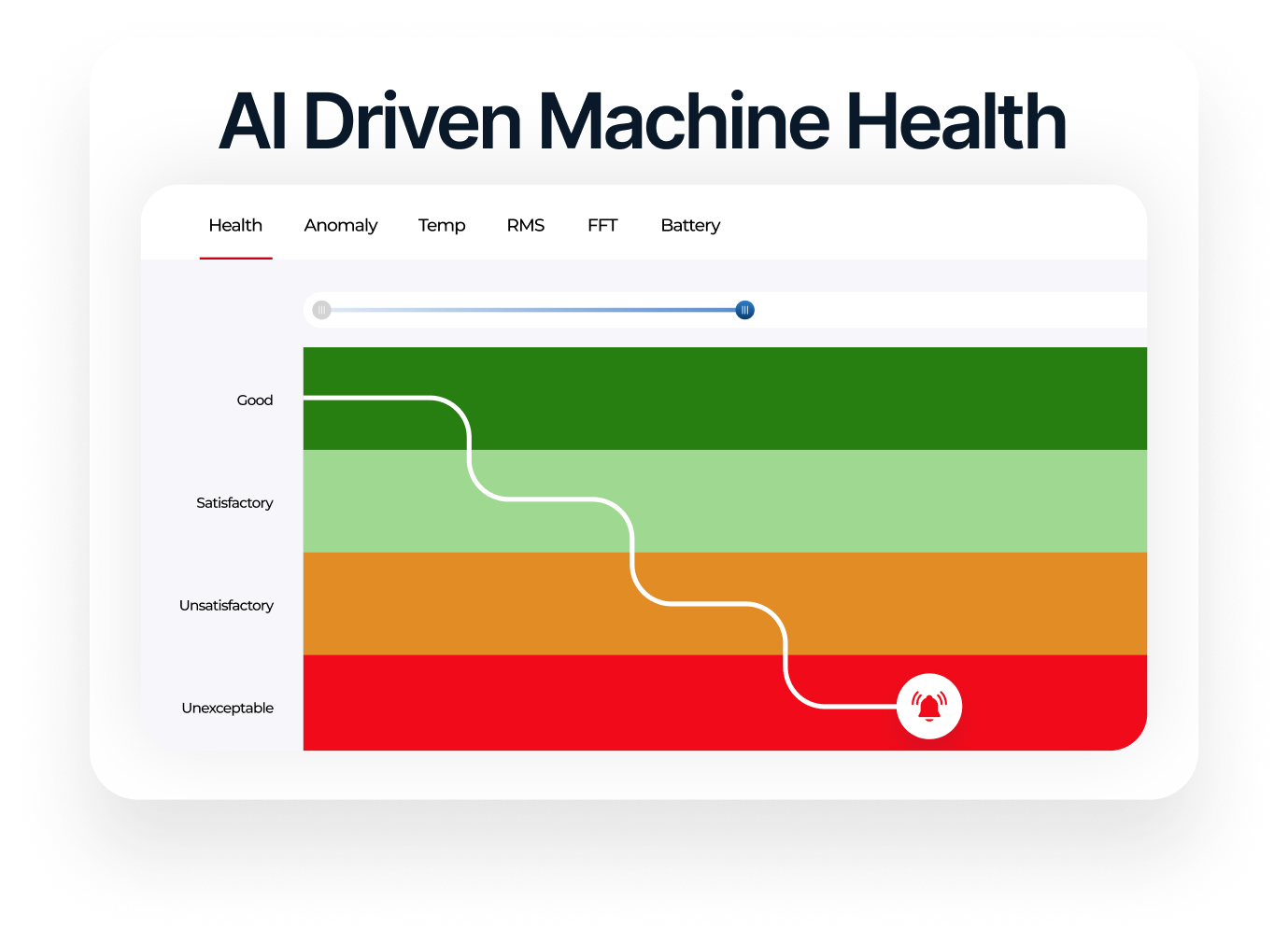

- Automated Health Insights: Hexastate’s AI algorithm provides automatic health estimations for machinery, offering a hands-off approach to monitoring.

- Predictive Failure Detection: It accurately predicts machine failures up to three months in advance, employing health and anomaly algorithms alongside various data inputs for comprehensive foresight.

- Eliminates Manual Analysis: Acting as an automated vibration analysis expert, the software removes the need for manual data interpretation, streamlining the maintenance process.

What is Hexastate Anomaly alarms?

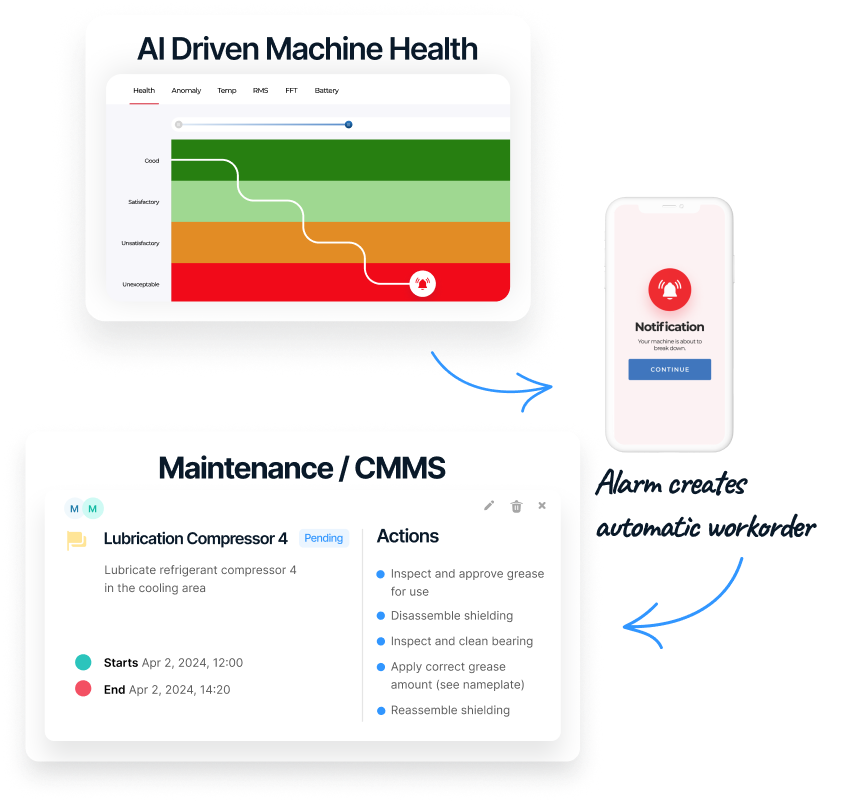

- Hexastates AI sets and manages alarms for you without you needing to do so.

- Anomaly algorithms look for patterns and alarm you when there is a change in the patterns.

- Receive notifications via SMS, email or automatically create a work order.

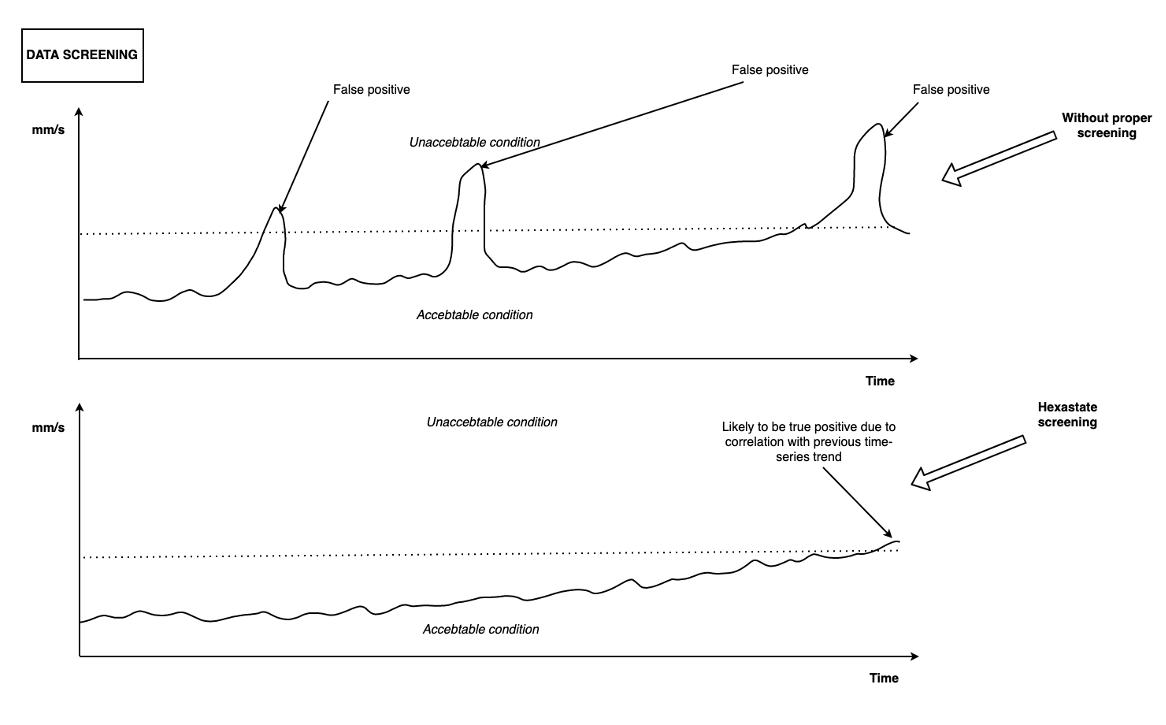

- Complex data is filtered, minimizing the risk of false positives and increasing the reliability of alarms.

- Continuous algorithm improvement for enhanced accuracy, meaning that most data we collect is used to optimize the algorithms anonymously.

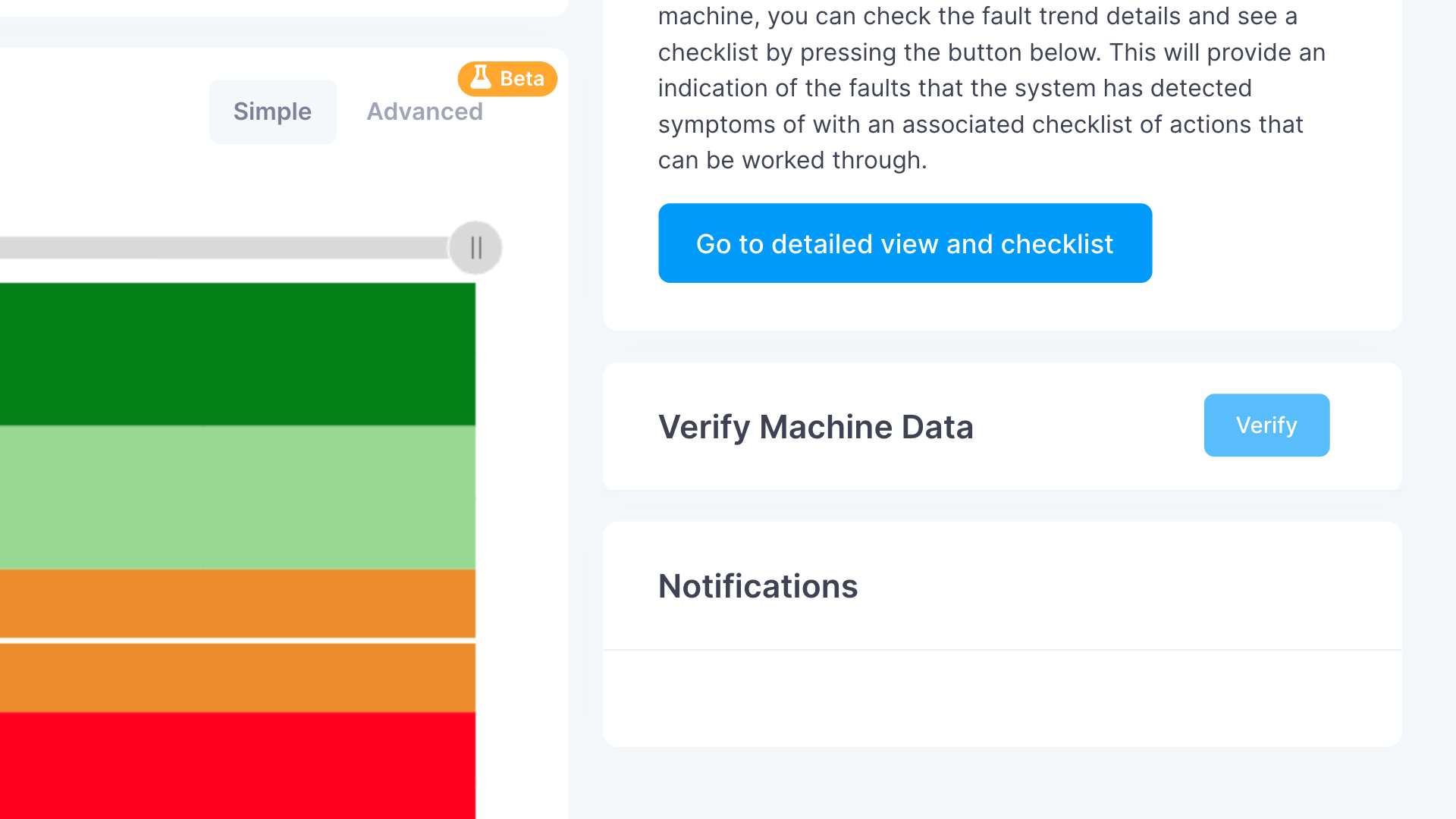

Verify machine data

- Verifying machine data is a service Hexastate provides. If you are in need of assistance of understanding a change in health, data or similar, you can request help directly to the Hexastate Support team for them to help.

- This remote service will provide feedback on the analysis, check mounting of sensors, connectivity and other related things that can impact the health estimation.

- Talk to sales to understand more about this feature.

Avoid false alarms using Automatic RPM Tracking

In some scenarios, we experience that the RPM of an asset may vary with time, if it has a Variable Frequency Drive (VFD). Therefore, we have to accommodate for this behaviour from the asset and analyze the data for probable RPM positions. Parts of the analysis are dependent on knowing the correct speed of the asset, which is why we have invested many hours in developing rules for estimating the exact speed of the asset. This is a key feature in having an accurate monitoring solution, because without this capability, a vibration expert doesn’t know where to look for any fault symptoms.

Get alarmed directly on SMS and E-mail, or in your CMMS

- Integrate the alarms directly into you CMMS if needed. Creating a work order for each condition change ensures that your maintenance team is notified, enabling them to plan the maintenance check up as they normally do as part of their routine.

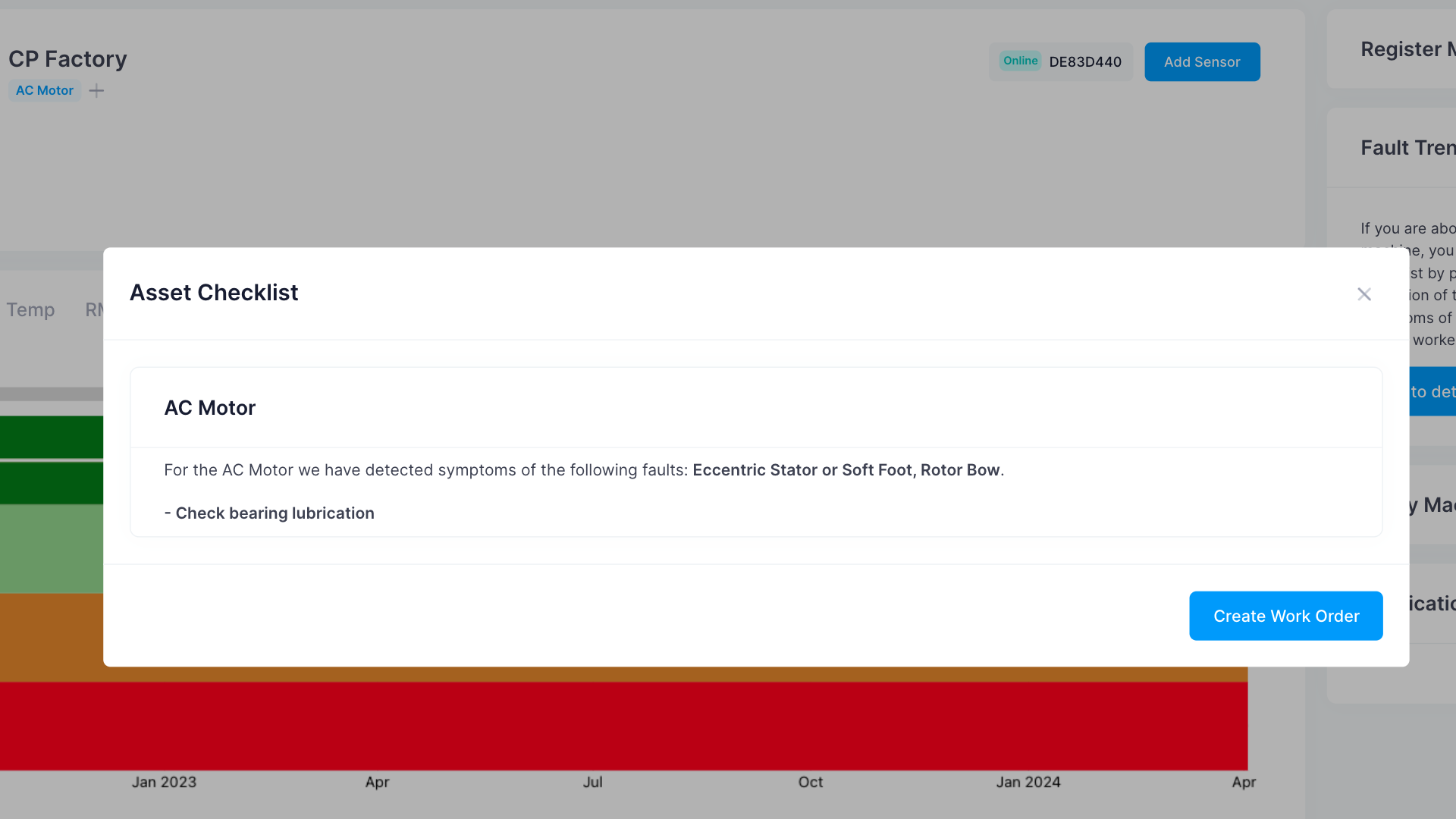

What is Hexastates fault trends?

- Automated fault symptom detection with Hexastates AI-software

- Automatically identifies issues like shaft unbalance and bearing wear.

- Eliminates the need for manual analysis, as the AI analyzes the data for you

- Converts faults into actionable automated checklists like you can see on the screen. The software can also create work orders in your CMMS if configured.