Below is an introduction to Hexastate’s fault diagnostics module and how its data-driven approach gives actionable feedback to the end-user.

Firstly, why did we develop the fault diagnostics module?

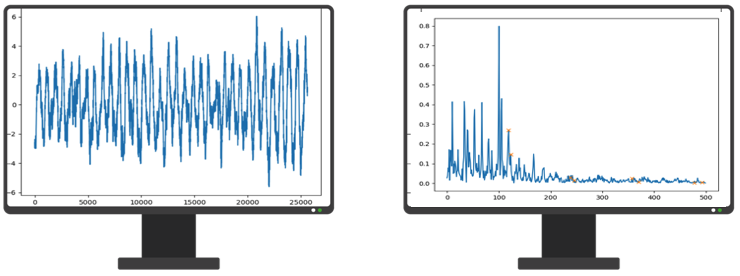

There are many software systems aiming to simplify the analysis of complex vibration data. While many are achieving this, knowledge of how to analyze the data is still required. This often involves years of experience and courses in order to become a vibration expert. Below are two pictures of common graphs used to analyze machine faults.

So, would it be possible to make algorithms that can act as a vibration expert? Could maintenance professionals on the floor act as though they had a vibration expert with them all along? Through thousands of hours of testing, trial and error, adaptations, and feedback, we have developed a fault diagnostics module that brings value to the end-user.

Next, how do we validate the output of the algorithms and determine their validity? During development, we found that there may be some faulty positives in the data. Similar symptoms can be displayed for different problems which can result in a faulty diagnosis. However, findings showed that most symptoms are associated with each other and can be interpreted differently.

Automation of the Vibration Expert

Through the process of automating the analysis of a vibration expert, the first aspect we looked at was how vibration experts analyze and make decisions. Even though there are many ways of looking and understanding vibrations, most traits remain the same as long as different variations are taken into account. Therefore, replicating how a vibration expert works have only been possible because we are using multiple analytical techniques, machine learning, and deep learning to understand patterns in the data, data variation, and data output.

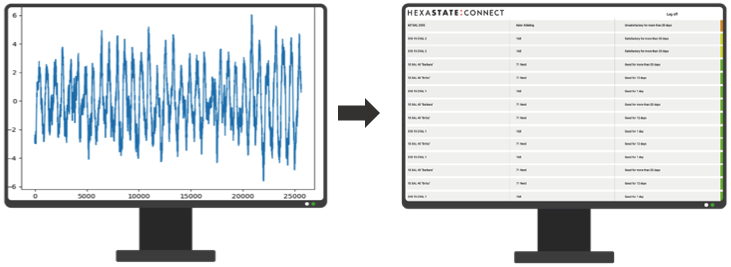

As a result, maintenance professionals know immediately what to do. This makes AI an efficient tool for maintenance professionals in all industries.

The screenshot below shows clients what it could mean for their organization-becoming data-driven with an AI-driven vibration expert in their pocket.

It is not realistic to ensure a 100 % accurate system to estimate when a machine will break down, then people will be overselling the product and AI; however, using AI to solve complex vibration data will help maintenance professionals make significantly better decisions faster, and thus reduce costs. An indication of the type of faults a machine has immediately increased the chance of better understanding the AI-driven trends of the machine, thus making it an essential tool for maintenance professionals.

Thank you for your time, and if you want to know more about what we work on at Hexastate, please do not hesitate to contact us.