Manage your Maintenance with Hexastate

Say goodbye to spreadsheets, pen and paper and the feeling that you’re not on top of things!

Solution Overview

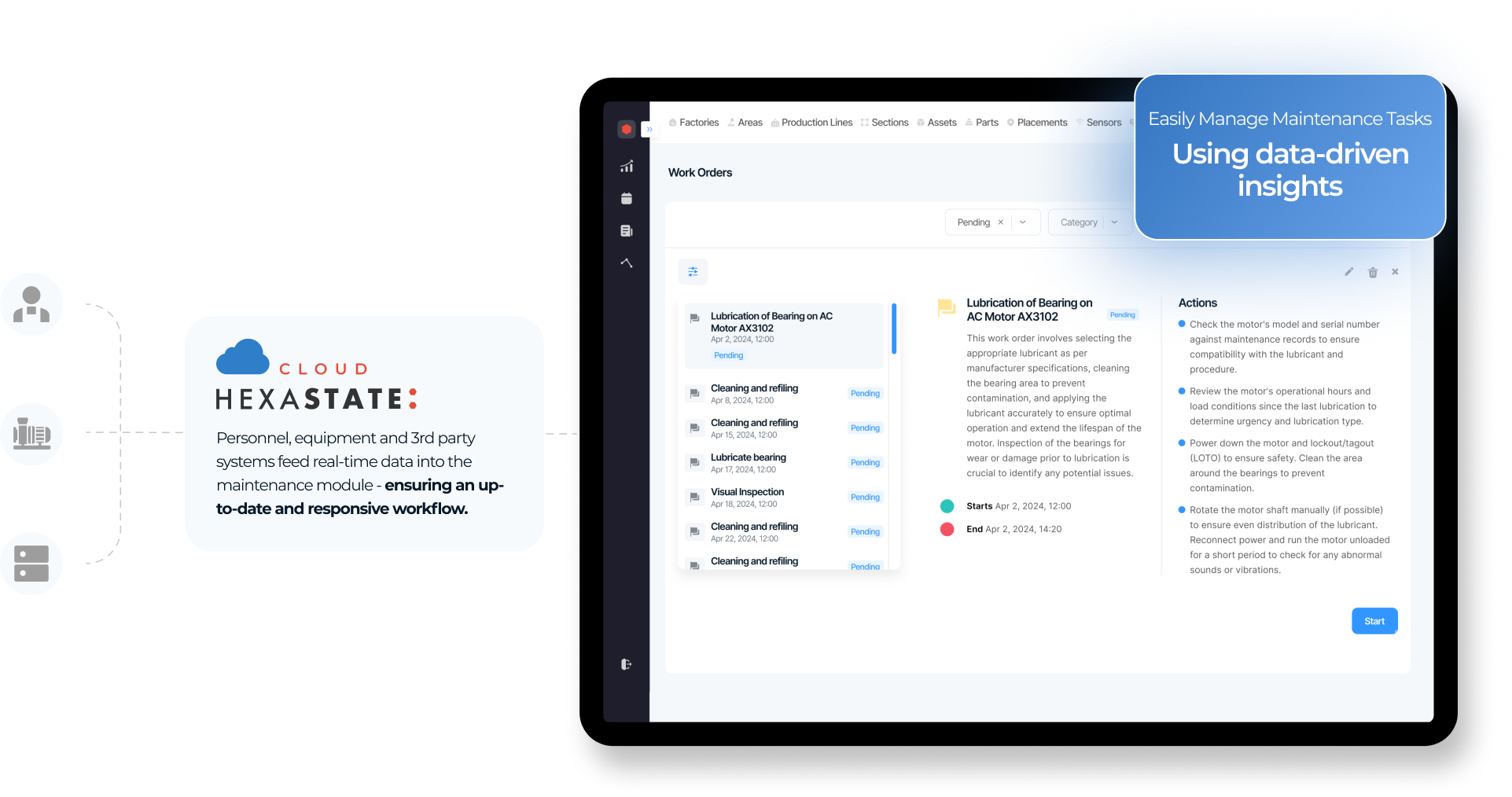

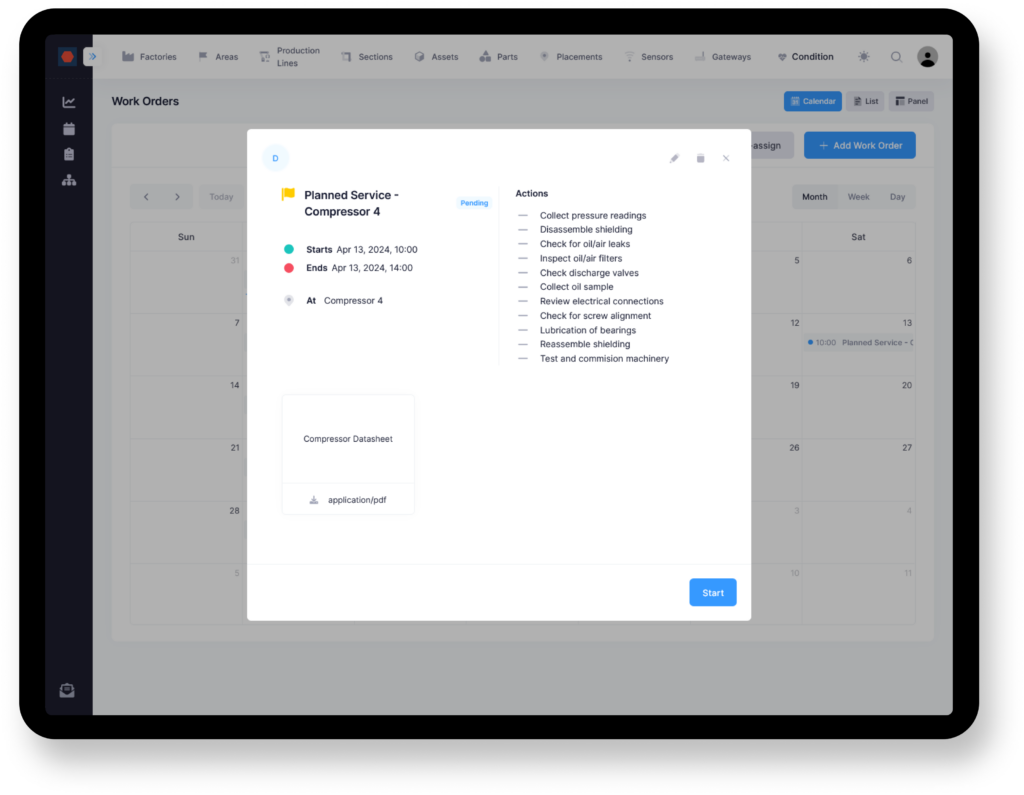

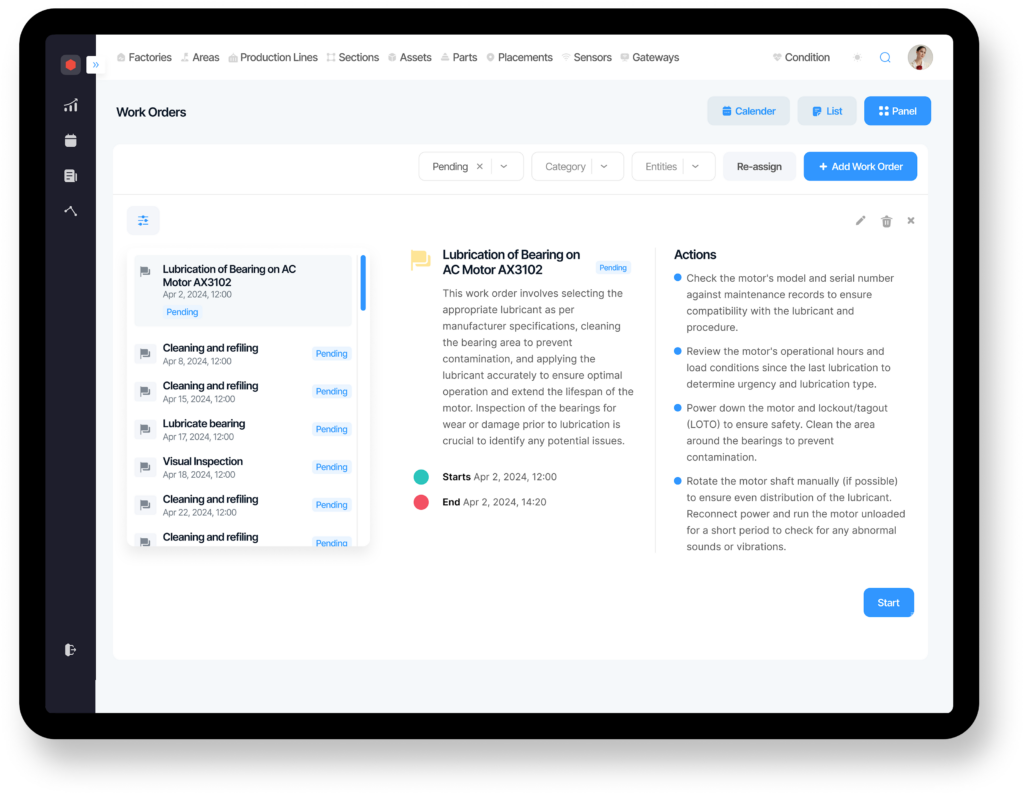

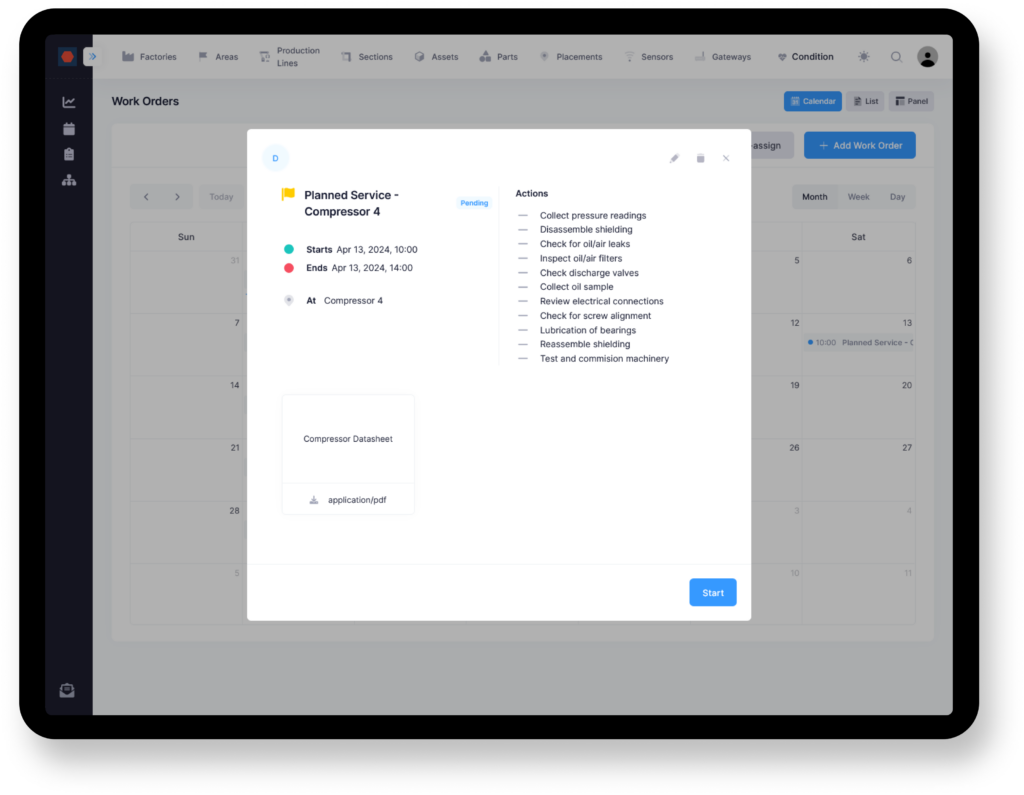

Work Order

Work Order Management

- Streamlined Maintenance Planning: Hexastate's Maintenance module allows you to work smarter, not harder. Managing your maintenance resources will now be smarter.

- Prioritized Tasks: Ensure work orders are performed in the right order for maximum efficiency, with easy priorization of tasks.

- Easily Adjust: Edit/Re-schedule work orders with just a few clicks.

- File Management: Easily include relevant files directly in your work orders to improve workflows and minimize downtime.

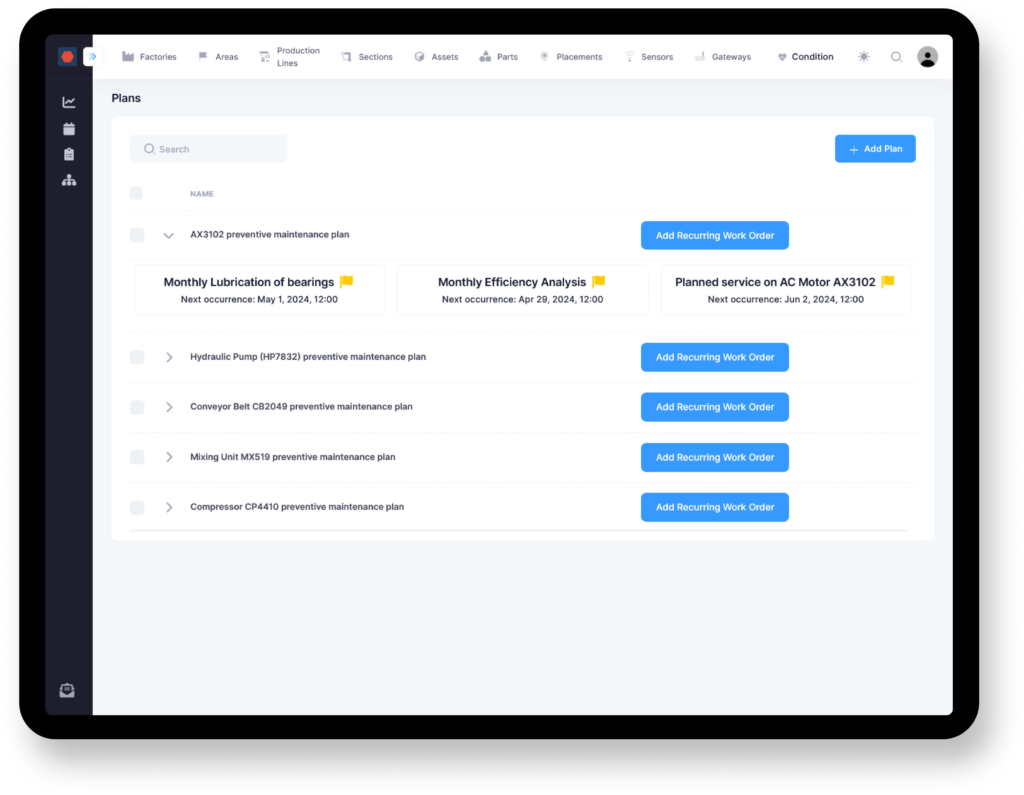

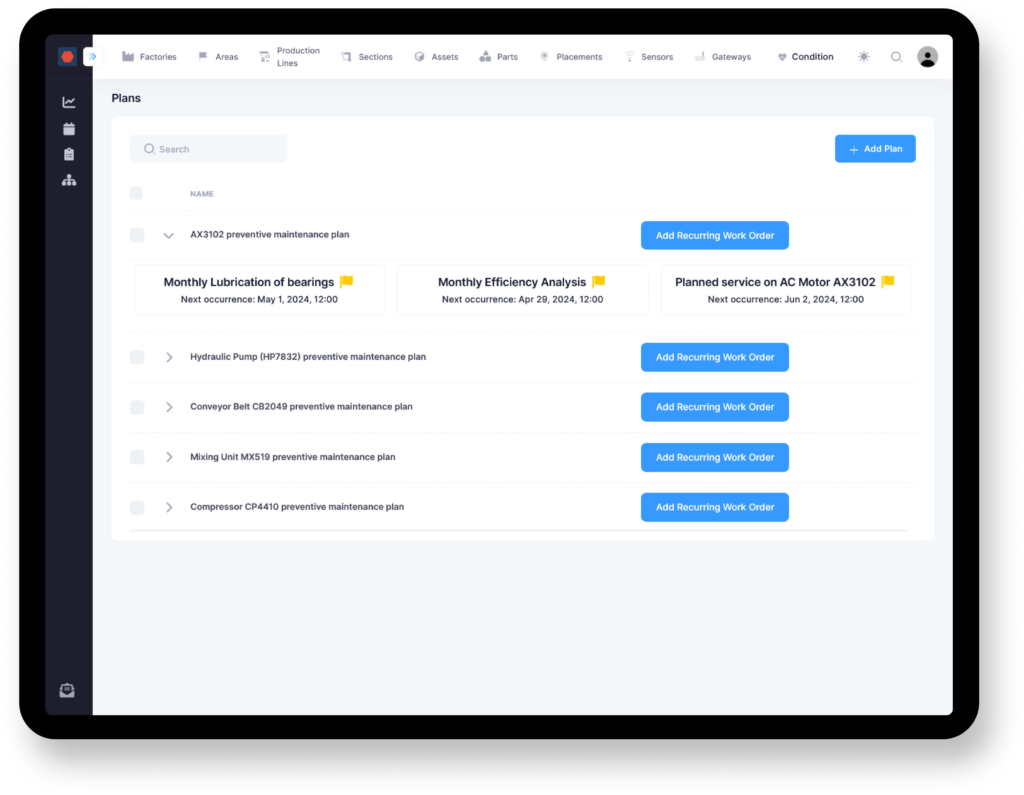

Preventive

Proactive Maintenance Scheduling

- Scheduled Precision: Set up recurring maintenance plans to keep your machinery running smoothly without guesswork.

- Operational Hours Tracking: Maintenance plans can be based on actual equipment usage, ensuring service is done right on time.

- Avoid Downtime: Data-driven preventive maintenance that helps prevent breakdowns, keeping your production on track.

- Ensure Equipment Lifetime: Consistent care prolongs the life of your machinery, ensuring you get the most out of your investment.

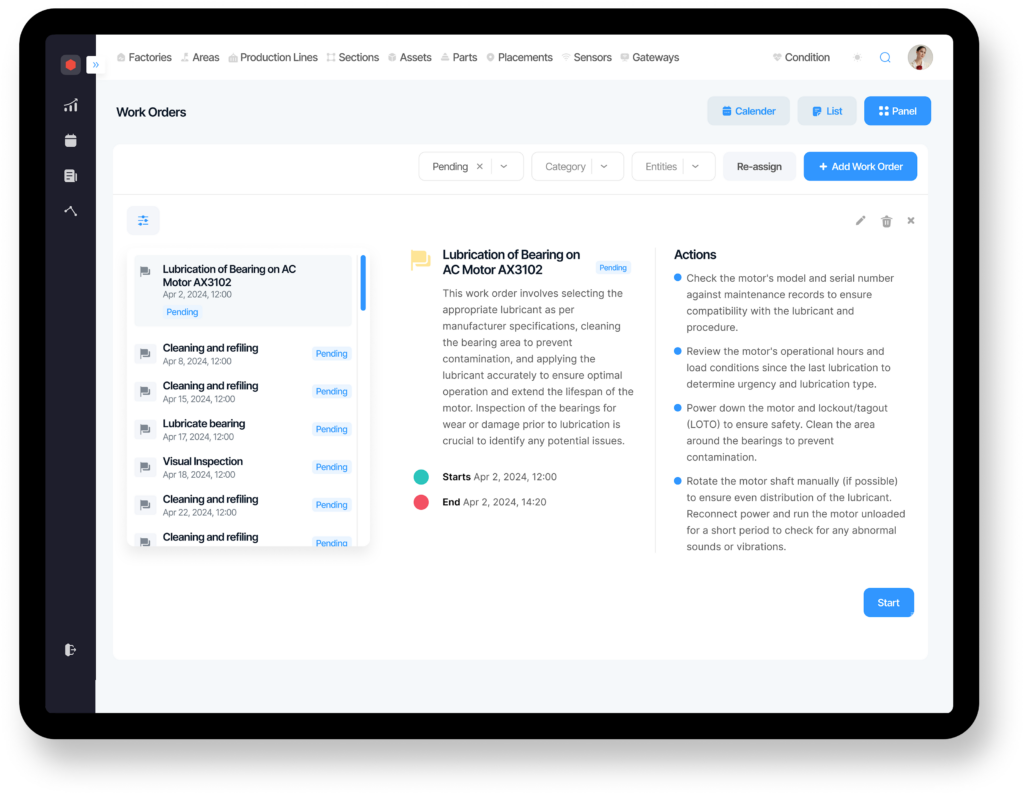

Easy Overview

Easy Maintenance Overview

- Flexible Viewing: Switch between different visual interfaces for various roles.

- Role-Based Permissions: Work Orders views can be adjusted based on the requirements of each role in the factory.

- Live Updates: Real-time updates of maintenance tasks keeps you informed with the latest updates, improving decision-making.

- Work Order Filtering: Refine your personal view with filters that sort work orders by assignment, machine specifics, etc.

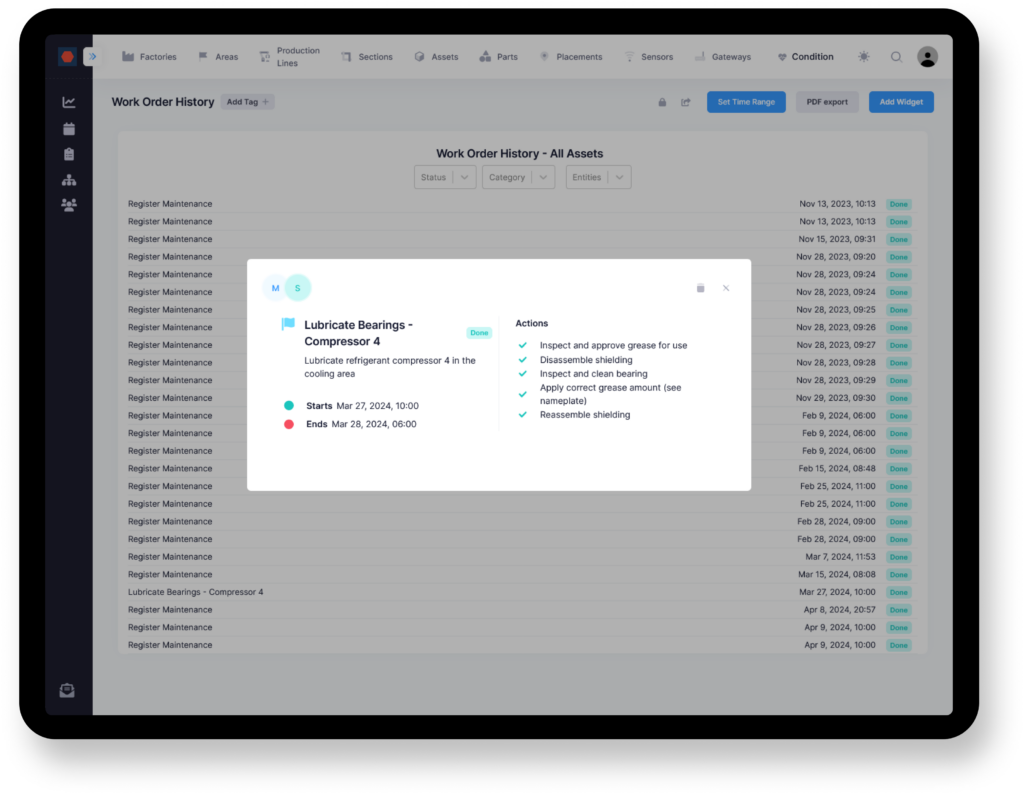

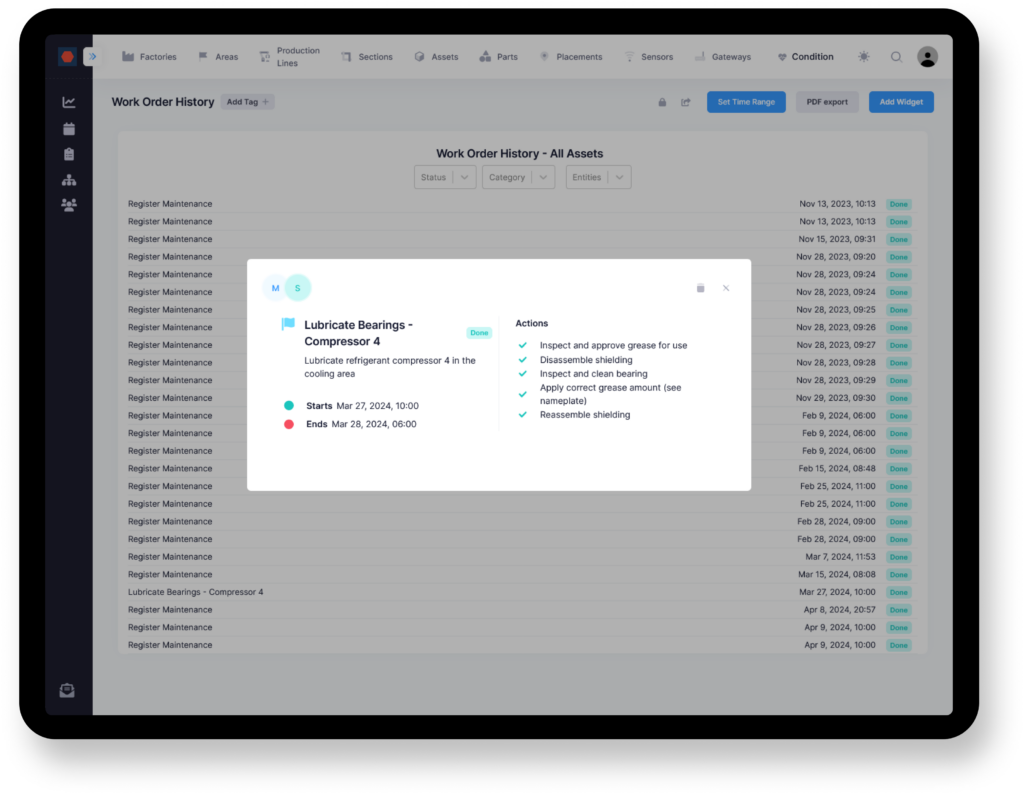

Log of history

Log of History

- Complete Asset Records: Every action taken on an asset is recorded, giving you a full history to reference anytime.

- Improved Strategic Planning: Use past data to make smarter maintenance decisions for the future.

- Proof of Performance: Maintain a detailed log to demonstrate maintenance diligence and asset care to stakeholders.

- Audit Readiness: With a complete history log, you’re always prepared for internal reviews or external audits.

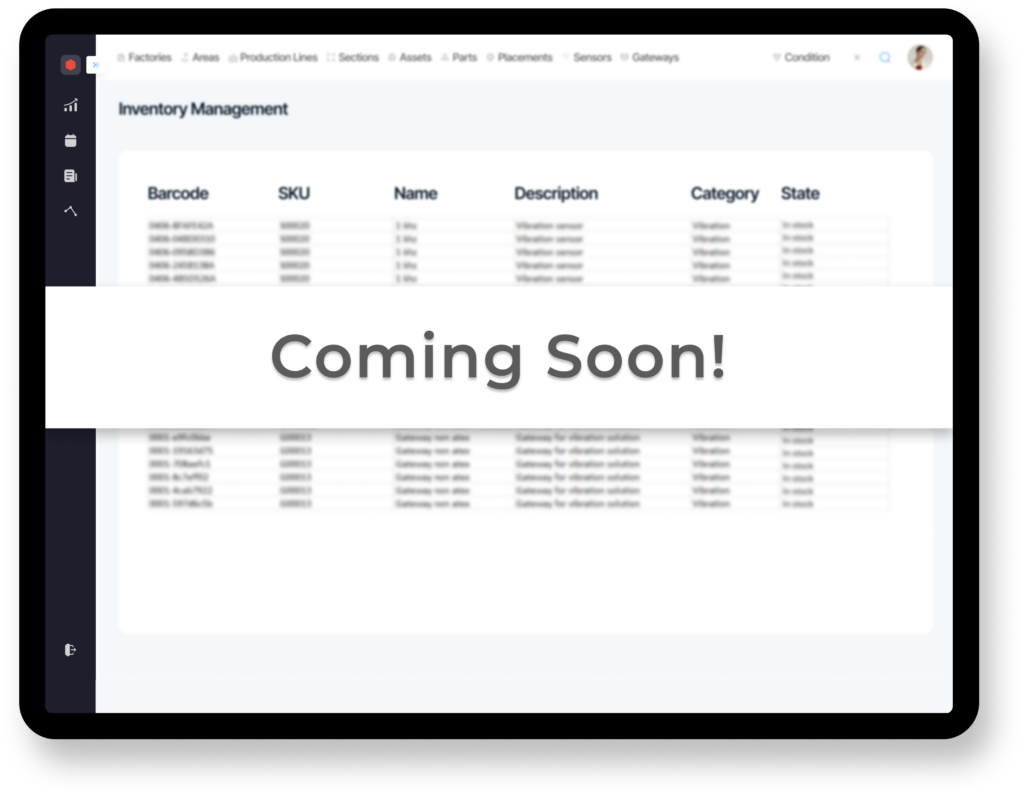

Inventory

Inventory Management (Coming Soon)

- Inventory Levels: Prevent overstocking and material shortages. Always know what’s in stock with live inventory tracking.

- Notice for Reordering: Set thresholds on inventory levels to automatically get notified when it's time to reorder parts, ensuring you never run out at a critical time.

- Parts Tracking: Keep track of how frequently parts are used.

- Supplier Info: Keep supplier information and order history at your fingertips, for easy reference and reordering.

- Cost Control: Analyze inventory costs over time to identify savings potential, and to optimize budgeting.

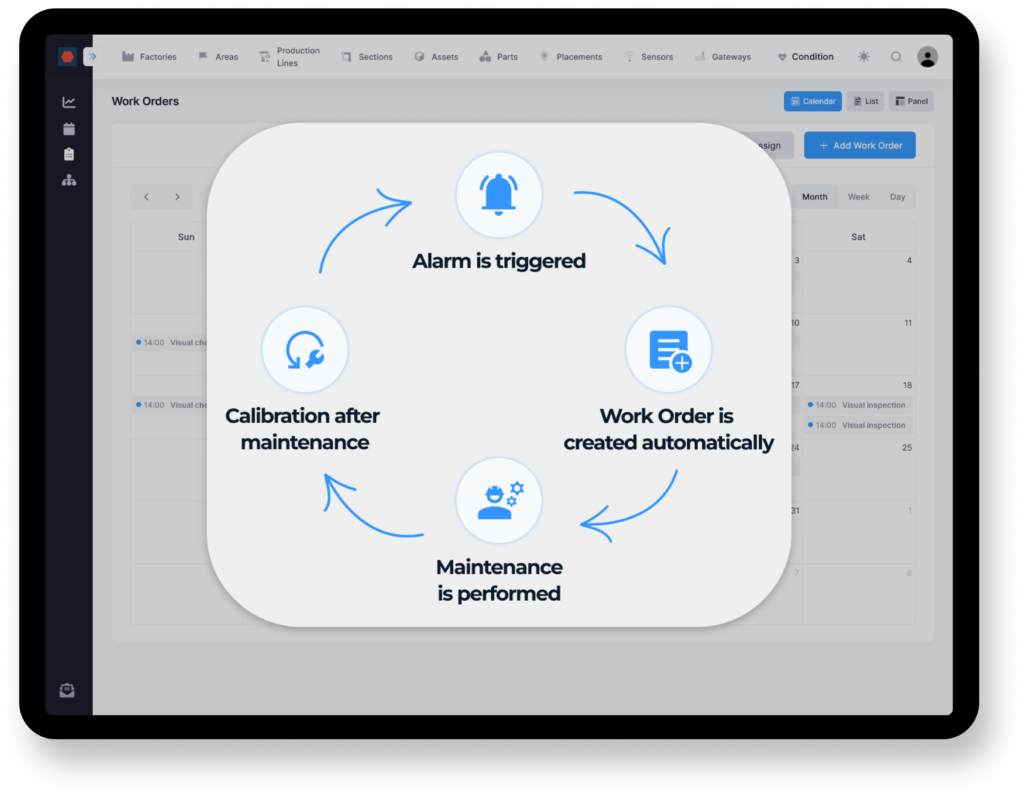

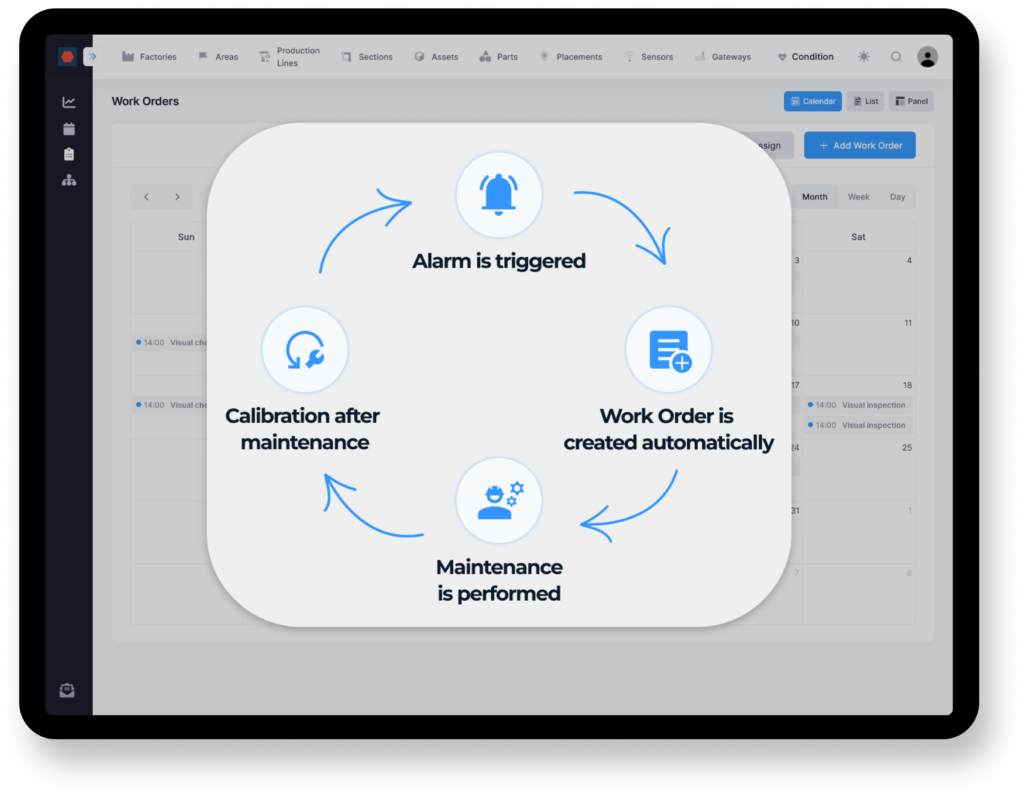

Integration

Work Order Integration

- Automate Work Orders: Automatically initiate work orders with corrective actions when machine conditions worsen, ensuring prompt maintenance response.

- Can be configured to automatically create Work Orders based on multiple types of alarms or triggers.

- Streamlining Operations: Simplify your maintenance workflows with automated work order generation from alarm signals.

- Efficiency and Accuracy: Increase the accuracy and efficiency of maintenance operations by automating responses to identified issues, making sure nothing is missed.

Your new toolbox

- Energy Optimization (EO)

- Front Page (FP)

- Production Optimization (PO)

- Globals (GBS)

- Machine Health (MH)

- Maintenance Planner (MP)

- Machine Health

- Energy Overview

- Work Order

- Condition Monitoring

- Analytics

- Fault Trends

- Preventive

- OEE

- ESG

- Alarms

- Easy Overview

- Energy Monitoring

- Hardware

- Maintenance

- Financial Understanding

- Log of history

- Dashboards

- Alarms

- Verify Machine Data

- Inventory

- Integrations

- Hardware

- Retrofit

- Maintenance Stats

- Dashboard Builder

- Overview of Plant

- Integration

- Understanding Uptime

- Dashboards

- Automations

- User Management

- Reports

- App Center

- API and Integrations

- Template Center

- OEE Dashboards

- Event Registration

- Management

- Operators

- Production Planner

- Analysis for OEE

- Alarms

- Data Collection

- MP: Dashboard Builder

Work Order

Work Order Management

- Streamlined Maintenance Planning: Hexastate's Maintenance module allows you to work smarter, not harder. Managing your maintenance resources will now be smarter.

- Prioritized Tasks: Ensure work orders are performed in the right order for maximum efficiency, with easy priorization of tasks.

- Easily Adjust: Edit/Re-schedule work orders with just a few clicks.

- File Management: Easily include relevant files directly in your work orders to improve workflows and minimize downtime.

Preventive

Proactive Maintenance Scheduling

- Scheduled Precision: Set up recurring maintenance plans to keep your machinery running smoothly without guesswork.

- Operational Hours Tracking: Maintenance plans can be based on actual equipment usage, ensuring service is done right on time.

- Avoid Downtime: Data-driven preventive maintenance that helps prevent breakdowns, keeping your production on track.

- Ensure Equipment Lifetime: Consistent care prolongs the life of your machinery, ensuring you get the most out of your investment.

Easy Overview

Easy Maintenance Overview

- Flexible Viewing: Switch between different visual interfaces for various roles.

- Role-Based Permissions: Work Orders views can be adjusted based on the requirements of each role in the factory.

- Live Updates: Real-time updates of maintenance tasks keeps you informed with the latest updates, improving decision-making.

- Work Order Filtering: Refine your personal view with filters that sort work orders by assignment, machine specifics, etc.

Log of history

Log of History

- Complete Asset Records: Every action taken on an asset is recorded, giving you a full history to reference anytime.

- Improved Strategic Planning: Use past data to make smarter maintenance decisions for the future.

- Proof of Performance: Maintain a detailed log to demonstrate maintenance diligence and asset care to stakeholders.

- Audit Readiness: With a complete history log, you’re always prepared for internal reviews or external audits.

Inventory

Inventory Management (Coming Soon)

- Inventory Levels: Prevent overstocking and material shortages. Always know what’s in stock with live inventory tracking.

- Notice for Reordering: Set thresholds on inventory levels to automatically get notified when it's time to reorder parts, ensuring you never run out at a critical time.

- Parts Tracking: Keep track of how frequently parts are used.

- Supplier Info: Keep supplier information and order history at your fingertips, for easy reference and reordering.

- Cost Control: Analyze inventory costs over time to identify savings potential, and to optimize budgeting.

Integration

Work Order Integration

- Automate Work Orders: Automatically initiate work orders with corrective actions when machine conditions worsen, ensuring prompt maintenance response.

- Can be configured to automatically create Work Orders based on multiple types of alarms or triggers.

- Streamlining Operations: Simplify your maintenance workflows with automated work order generation from alarm signals.

- Efficiency and Accuracy: Increase the accuracy and efficiency of maintenance operations by automating responses to identified issues, making sure nothing is missed.