Fault trend detection

Automatically identifies issues like shaft unbalance and bearing wear

What is Hexastates fault trends?

- Hexastates AI Analysis engine provides automated fault symptom detection.

- Automatically identifies issues like shaft unbalance and bearing wear.

- Eliminates the need for manual analysis, as the AI analyzes the data for you.

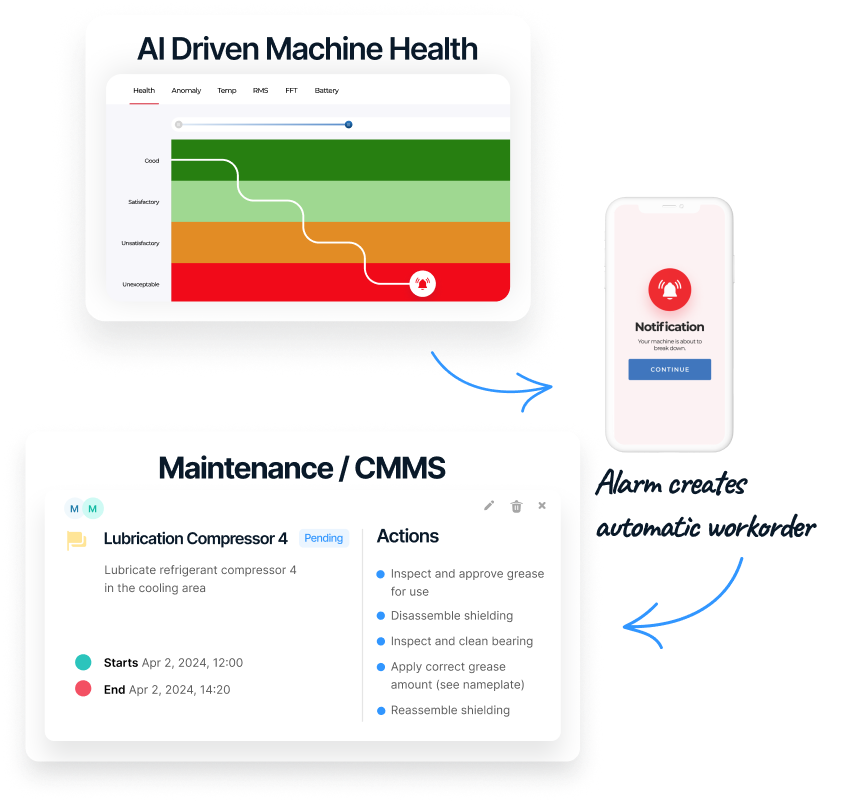

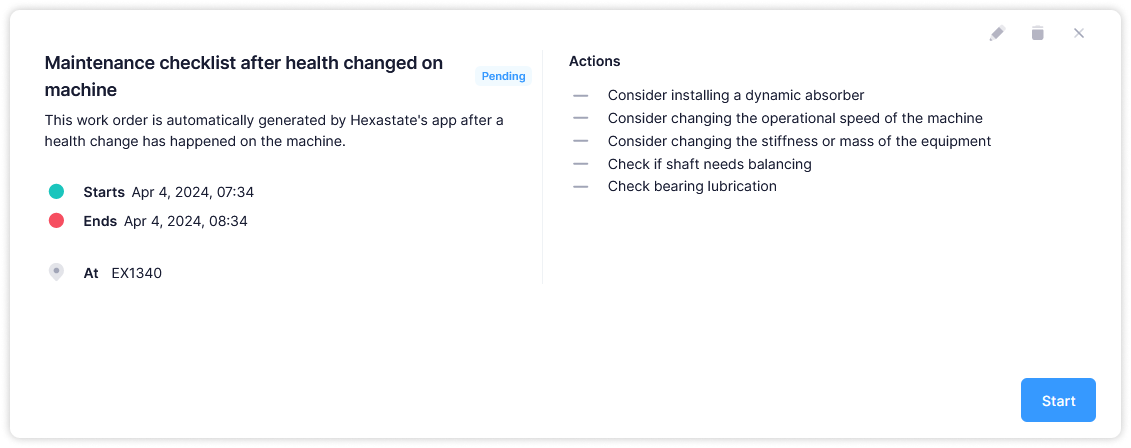

- Converts faults into actionable automated checklists like you can see on the screen. The software can also create work orders in your CMMS if configured.

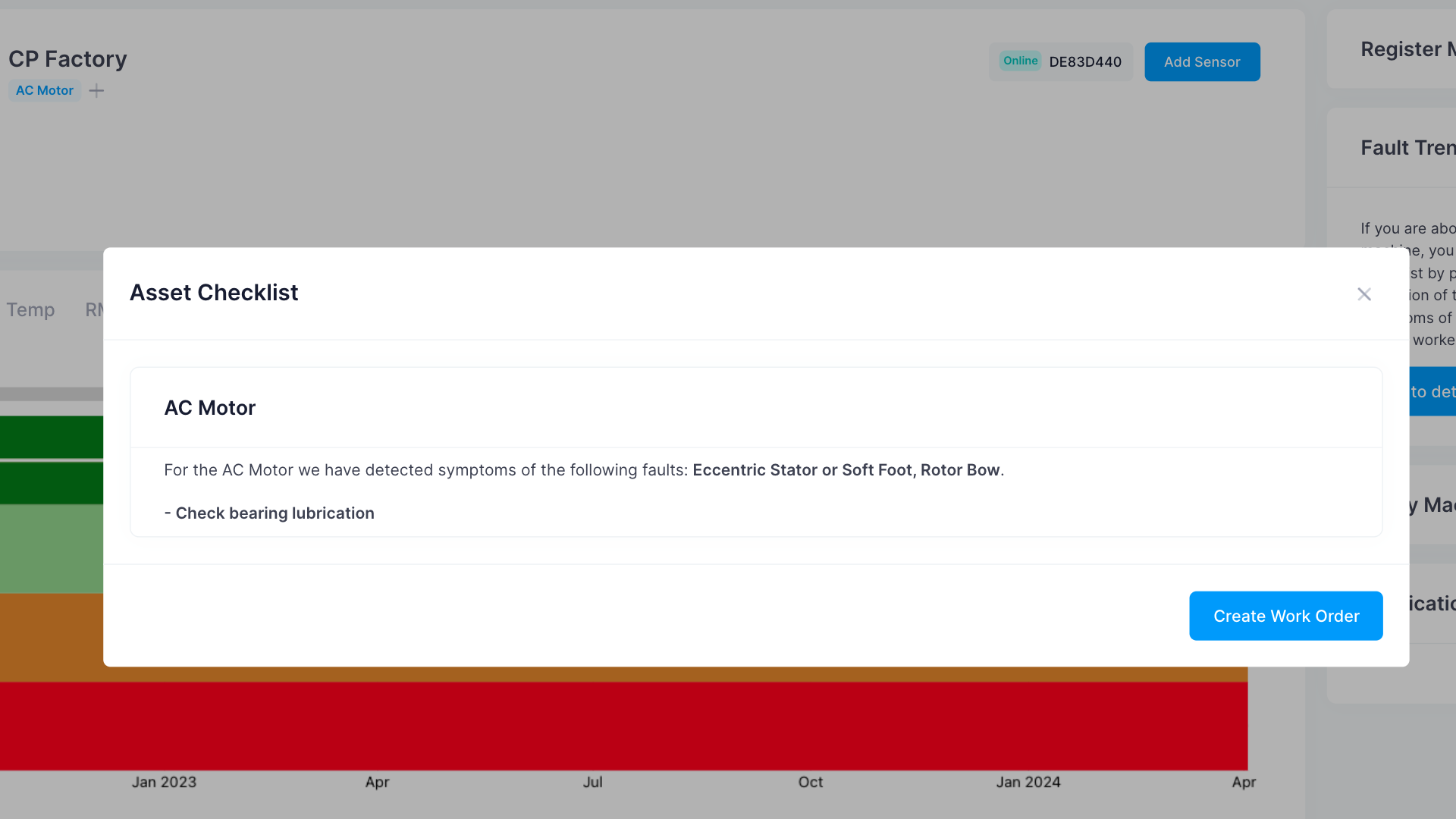

What is the Hexastate Checklist?

- Automatically generated maintenance checklists based on machine data.

- Identifies necessary maintenance actions when changes in machine health are detected.

- Clear, actionable steps for maintenance personnel to follow, ensuring thorough and effective repairs.

- Reduction in downtime by proactively managing potential issues before they escalate.

- Checklists can be used stand-alone or directly integrated into work orders.

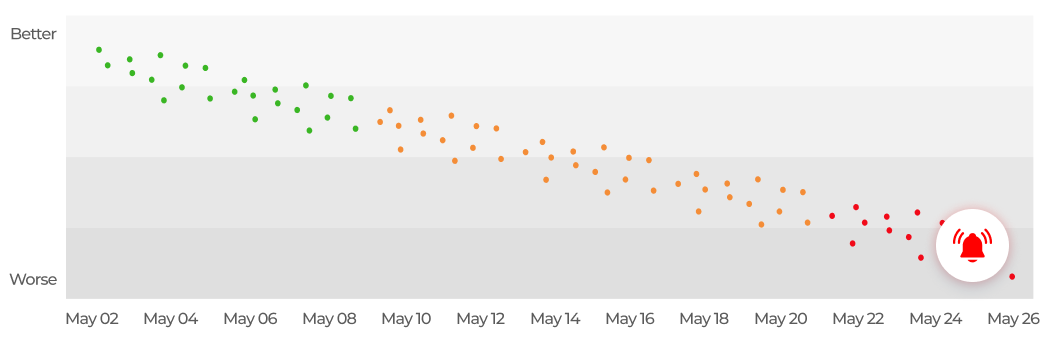

What is Hexastate Anomaly alarms?

- Hexastates AI sets and manages alarms for you without you needing to do so.

- Anomaly algorithms look for patterns and alarm you when there is a change in the patterns.

- Receive notifications via SMS or email, or automatically create a work order.

- Complex data is filtered, minimizing the risk of false positives and increasing the reliability of alarms.

- Continuous algorithm improvement for enhanced accuracy, meaning that most data we collect is used to optimize the algorithms anonymously.

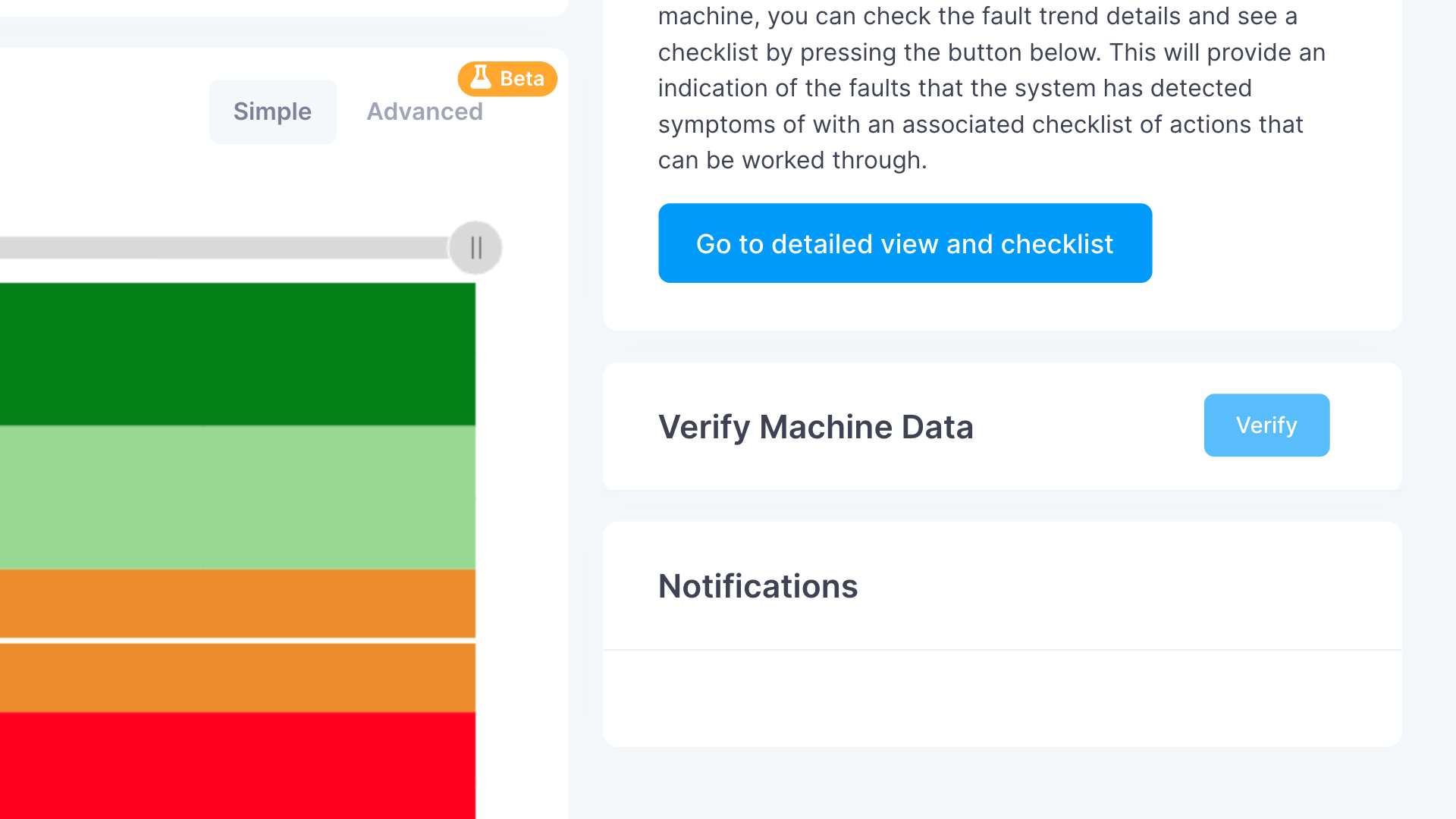

Verify machine data

- Verifying machine data is a service Hexastate provides. If you are in need of assistance of understanding a change in health, data or similar, you can request help directly to the Hexastate Support team for them to help.

- This remote service will provide feedback on the analysis, check mounting of sensors, connectivity and other related things that can impact the health estimation.

- Talk to sales to understand more about this feature.

Get the alarm directly in your CMMS

- Integrate the alarms directly into you CMMS if needed. Creating a work order for each condition change ensures that your maintenance team is notified, enabling them to plan the maintenance check up as they normally do as part of their routine.