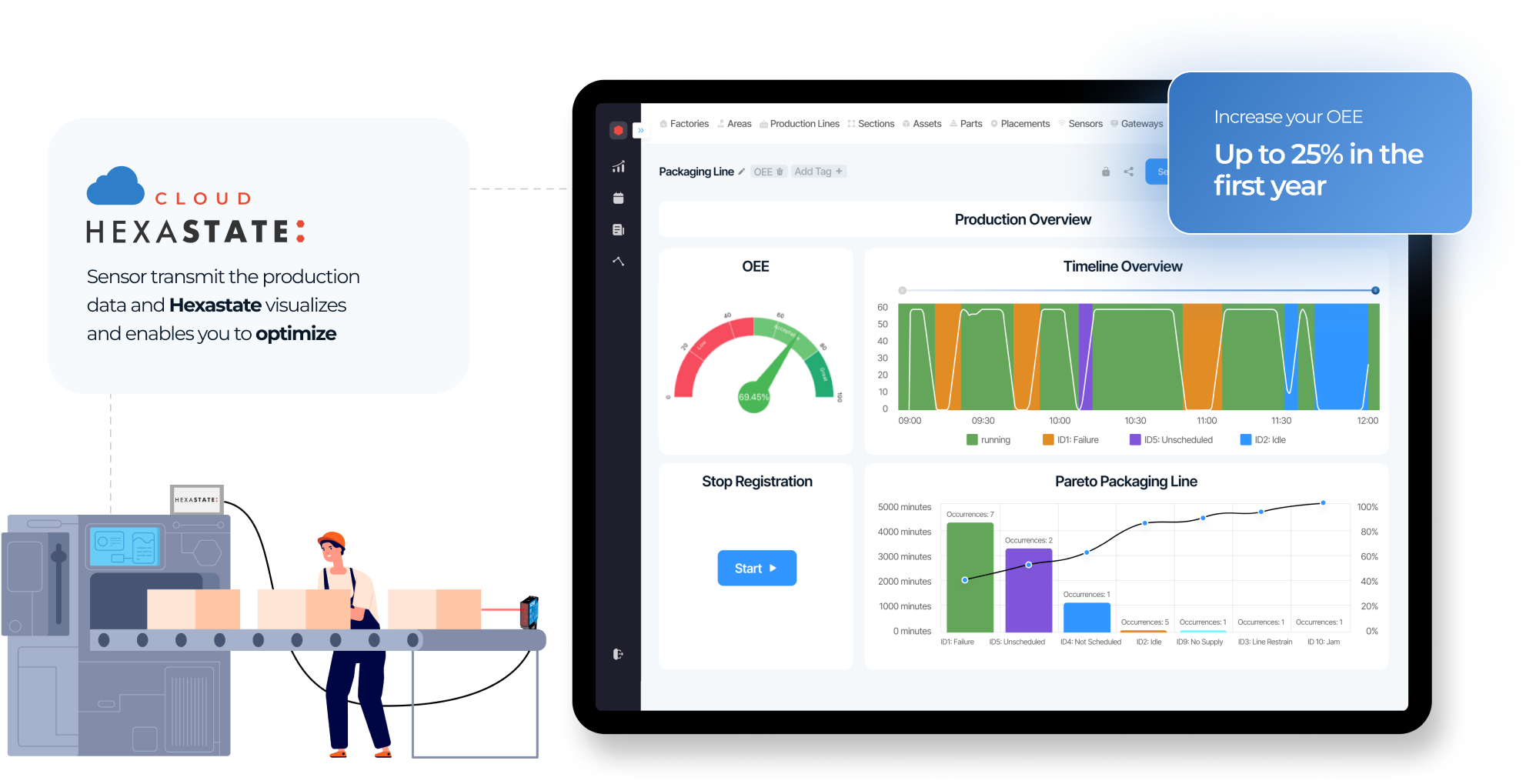

Transform Data into Performance

Experience a platform that converts raw data into actionable insights for superior operational performance.

Solution Overview

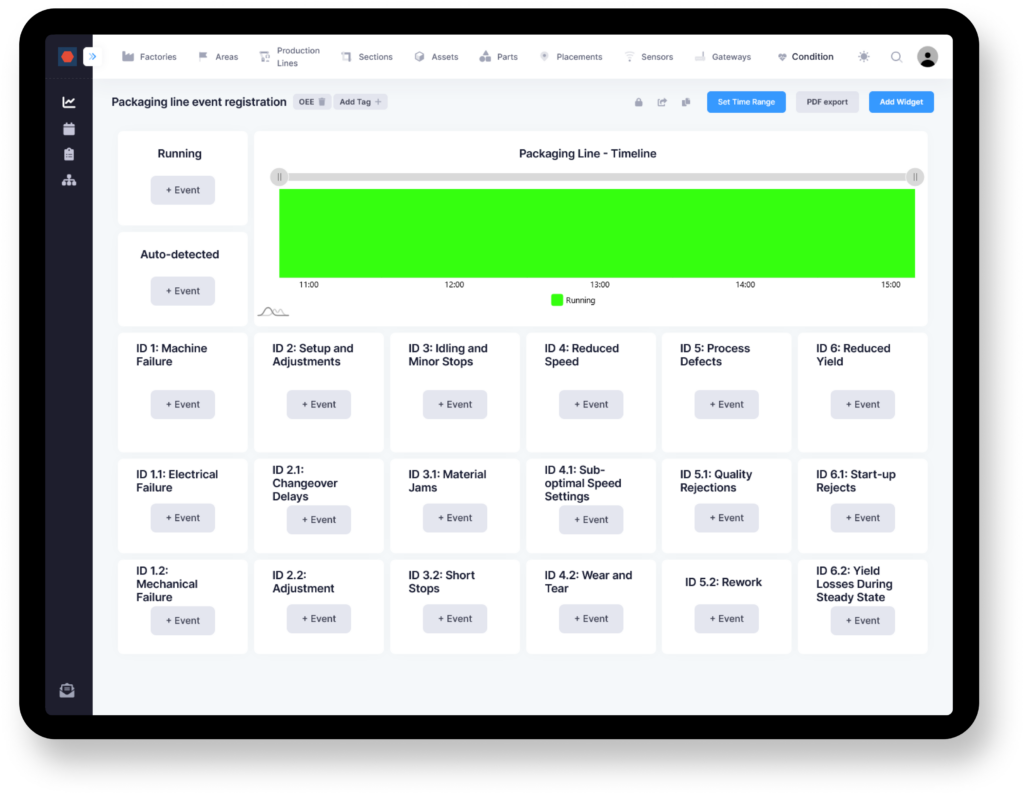

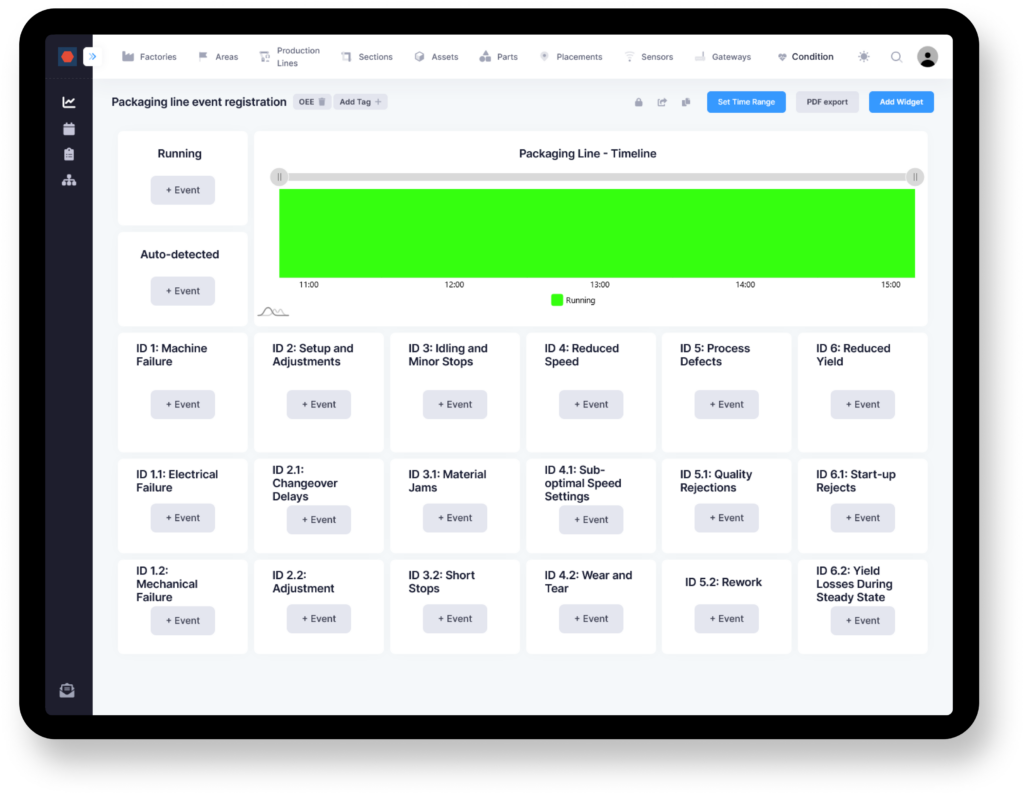

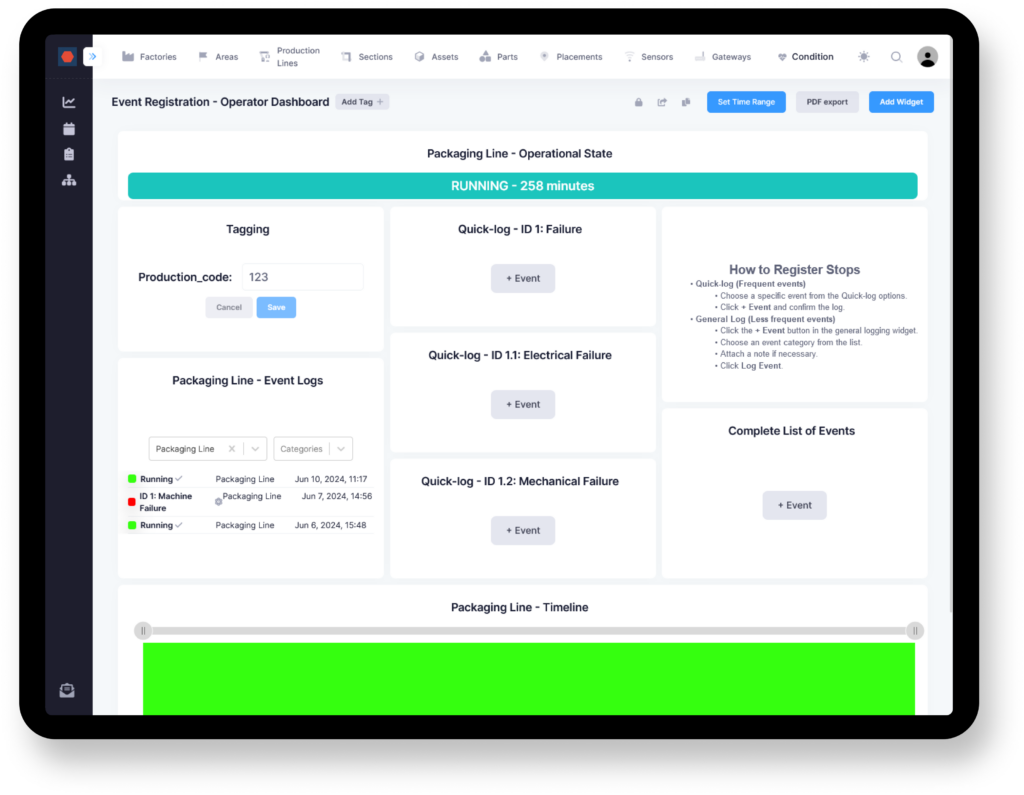

Event Registration

Event/Stop Registration

- Ease of Use: Hexastates event registration feature allows for an user-friendly interface, customized for quick and easy logging of events.

- Quick Response: Enable operators to record the causes for downtime immediately, enhancing troubleshooting capabitilies, as well as documentation.

- Enriched data: Improve your data accuracy with streamlined event registration, supporting the implementation of effective strategies.

- For example, you can combine energy data with event registration to understand the causes for energy usage.

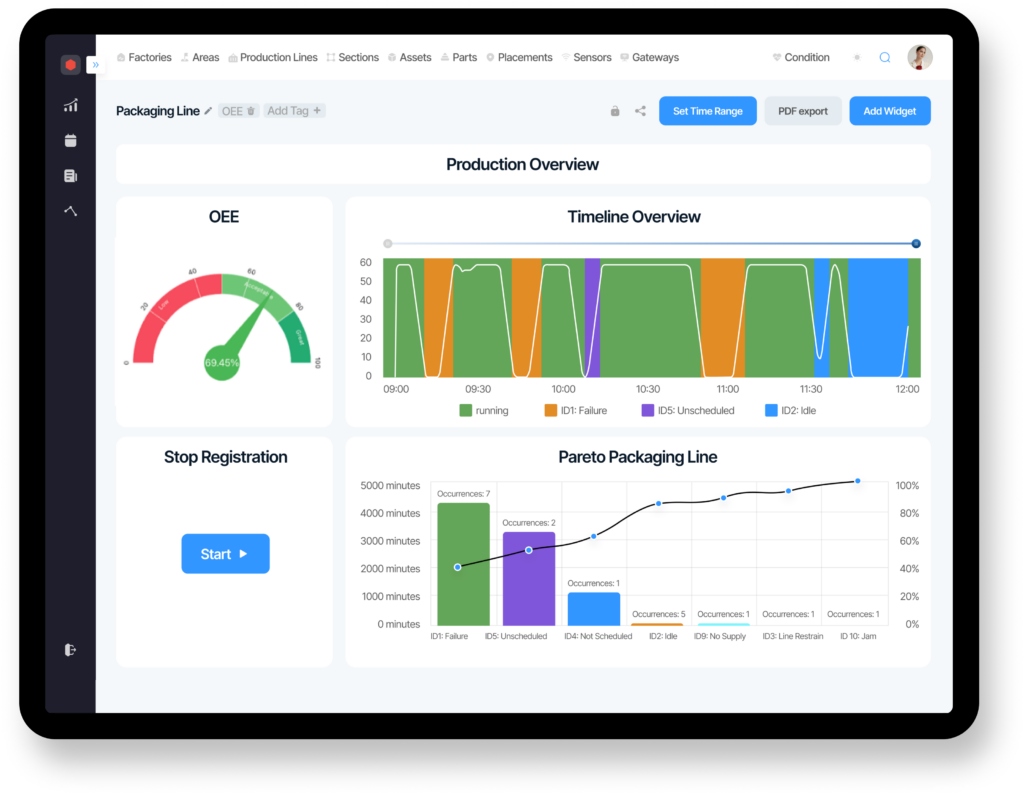

Management

Dashboards for Management

- Strategic Oversight: Equip managers with comprehensive views of OEE data for making informed strategic decisions.

- Real-Time Management: Get the benefit of quick responses to production issues, with live operational data.

- Performance Benchmarking: Benchmark internally to guide continuous improvement and align team objectives.

- Cost Control: Identify inefficiencies and reduce costs through detailed, targeted insights.

Operators

Dashboards for Operators

- Instant Overview: Provide operators with concise real-time data to improve immediate task planning.

- Operational Efficiency: Operators can monitor their own performance to identify and reduce inefficiencies in their workflows.

- Improved Operations: Operators can configure and get essential alerts and instructions for different events, enhancing day-to-day work and safety.

- Progress Tracking: Allow operators to see their contribution to targets and goals, motivating consistent performance.

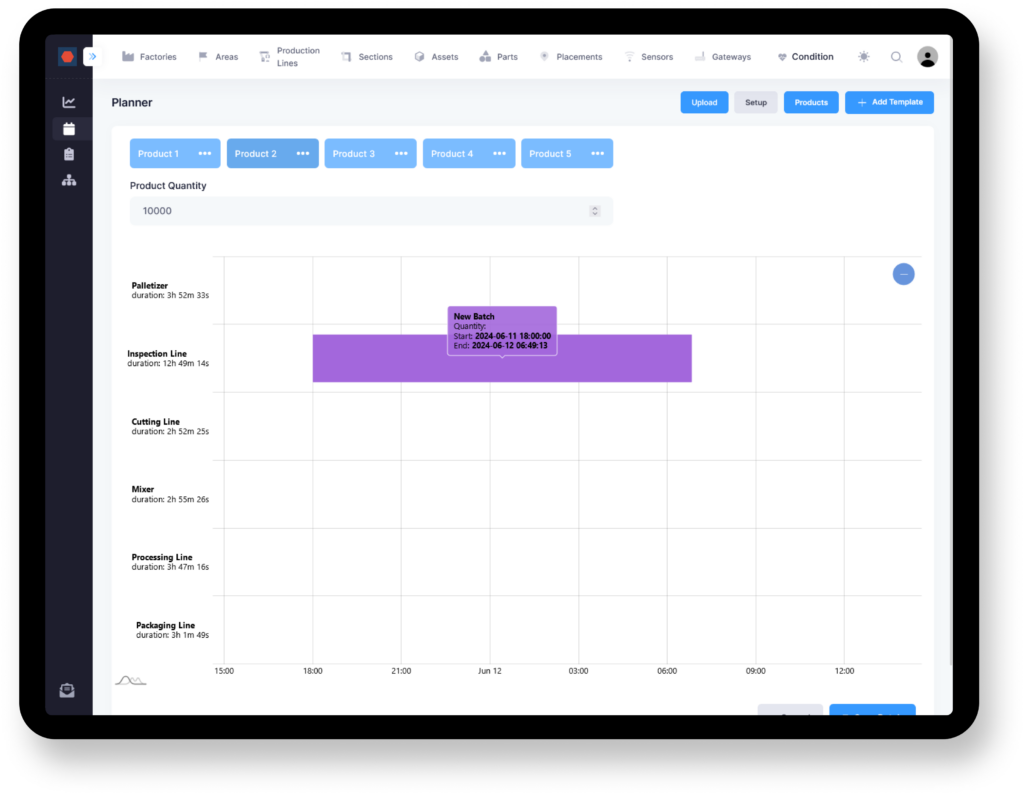

Production Planner

Production Planner

- Optimized Scheduling: Streamline production workflows with flexible scheduling that aligns with resource availability.

- Real-Time Adjustments: Adapt new plans dynamically based on live operational data, ensuring optimal productivity and efficiency.

- Staying on Target: Help teams meet production targets through clear communication of daily goals and expectations.

Analysis for OEE

Analysis for OEE

- Deep Insights: Use advanced analytics to dive into efficiency metrics and their related data, uncovering previously hidden opportunities for improvement.

- Trend Analysis: Track performance trends over time to predict potential issues and adjust processes preemptively.

- Root Cause Identification: Pinpoint the exact causes of inefficiencies to effectively target your corrective actions to eliminate issues.

- Performance Optimization: Use data-driven insights to refine operations, boost OEE scores, and enhance overall productivity and employee satisfaction.

Data Collection

Data Collection

- Automated Collection: Capture operational data automatically using plug-and-play hardware, or integrate into existing systems to avoid manual entry errors.

- Real-Time Monitoring: Install sensors to track machine activity and production stops instantly, feeding accurate data for OEE analysis.

- Uploading or synchronizing production data periodically is also possible.

- Event Logging: Equip operators with easy-to-use interfaces to log events quickly, ensuring detailed and precise enrichment of the collected data.

Your new toolbox

- Energy Optimization (EO)

- Front Page (FP)

- Production Optimization (PO)

- Globals (GBS)

- Machine Health (MH)

- Maintenance Planner (MP)

- Machine Health

- Energy Overview

- Work Order

- Condition Monitoring

- Analytics

- Fault Trends

- Preventive

- OEE

- ESG

- Alarms

- Easy Overview

- Energy Monitoring

- Hardware

- Maintenance

- Financial Understanding

- Log of history

- Dashboards

- Alarms

- Verify Machine Data

- Inventory

- Integrations

- Hardware

- Retrofit

- Maintenance Stats

- Dashboard Builder

- Overview of Plant

- Integration

- Understanding Uptime

- Dashboards

- Automations

- User Management

- Reports

- App Center

- API and Integrations

- Template Center

- OEE Dashboards

- Event Registration

- Management

- Operators

- Production Planner

- Analysis for OEE

- Alarms

- Data Collection

- MP: Dashboard Builder

Event Registration

Event/Stop Registration

- Ease of Use: Hexastates event registration feature allows for an user-friendly interface, customized for quick and easy logging of events.

- Quick Response: Enable operators to record the causes for downtime immediately, enhancing troubleshooting capabitilies, as well as documentation.

- Enriched data: Improve your data accuracy with streamlined event registration, supporting the implementation of effective strategies.

- For example, you can combine energy data with event registration to understand the causes for energy usage.

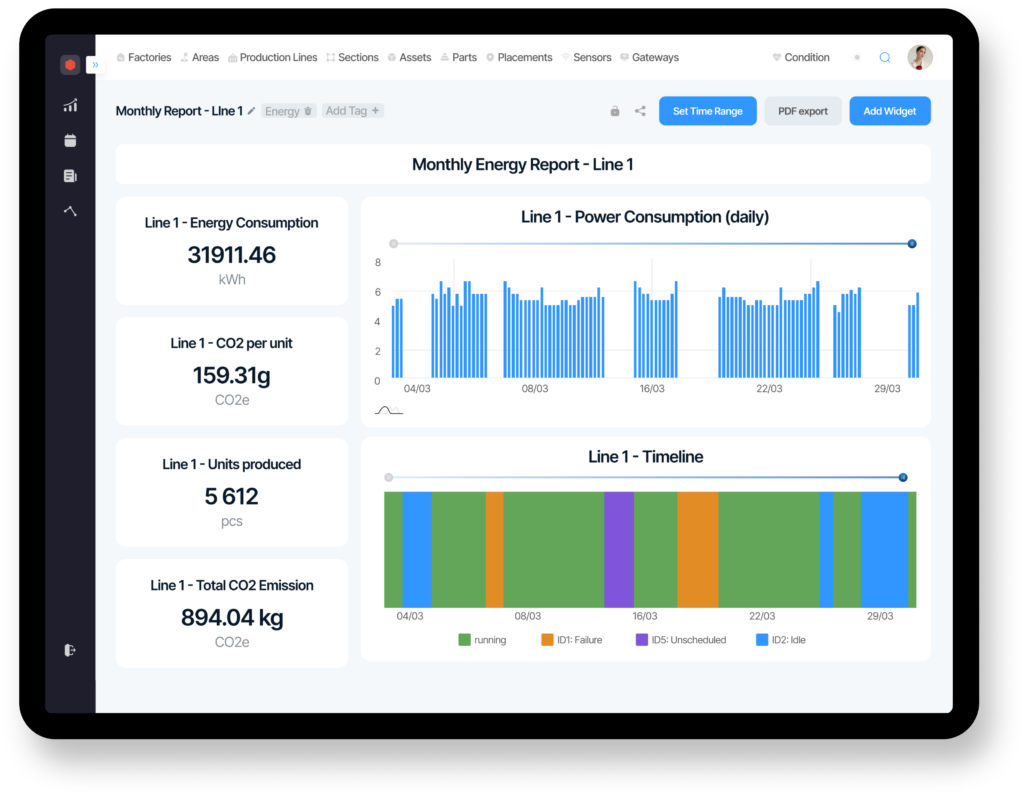

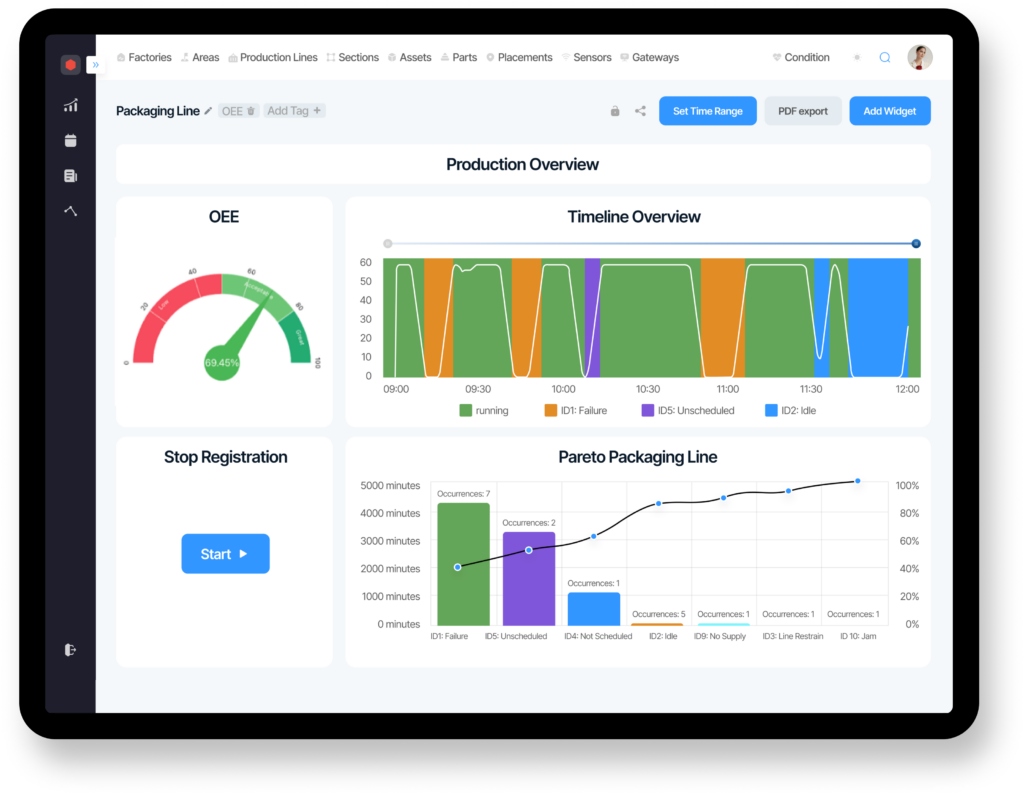

Management

Dashboards for Management

- Strategic Oversight: Equip managers with comprehensive views of OEE data for making informed strategic decisions.

- Real-Time Management: Get the benefit of quick responses to production issues, with live operational data.

- Performance Benchmarking: Benchmark internally to guide continuous improvement and align team objectives.

- Cost Control: Identify inefficiencies and reduce costs through detailed, targeted insights.

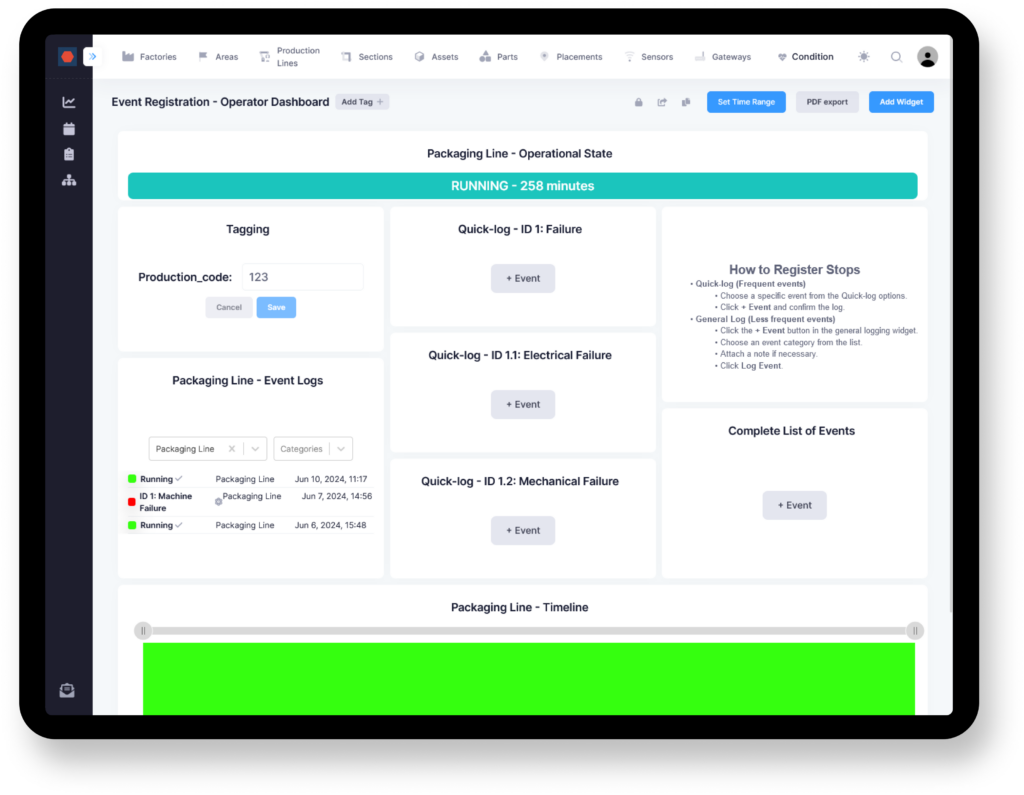

Operators

Dashboards for Operators

- Instant Overview: Provide operators with concise real-time data to improve immediate task planning.

- Operational Efficiency: Operators can monitor their own performance to identify and reduce inefficiencies in their workflows.

- Improved Operations: Operators can configure and get essential alerts and instructions for different events, enhancing day-to-day work and safety.

- Progress Tracking: Allow operators to see their contribution to targets and goals, motivating consistent performance.

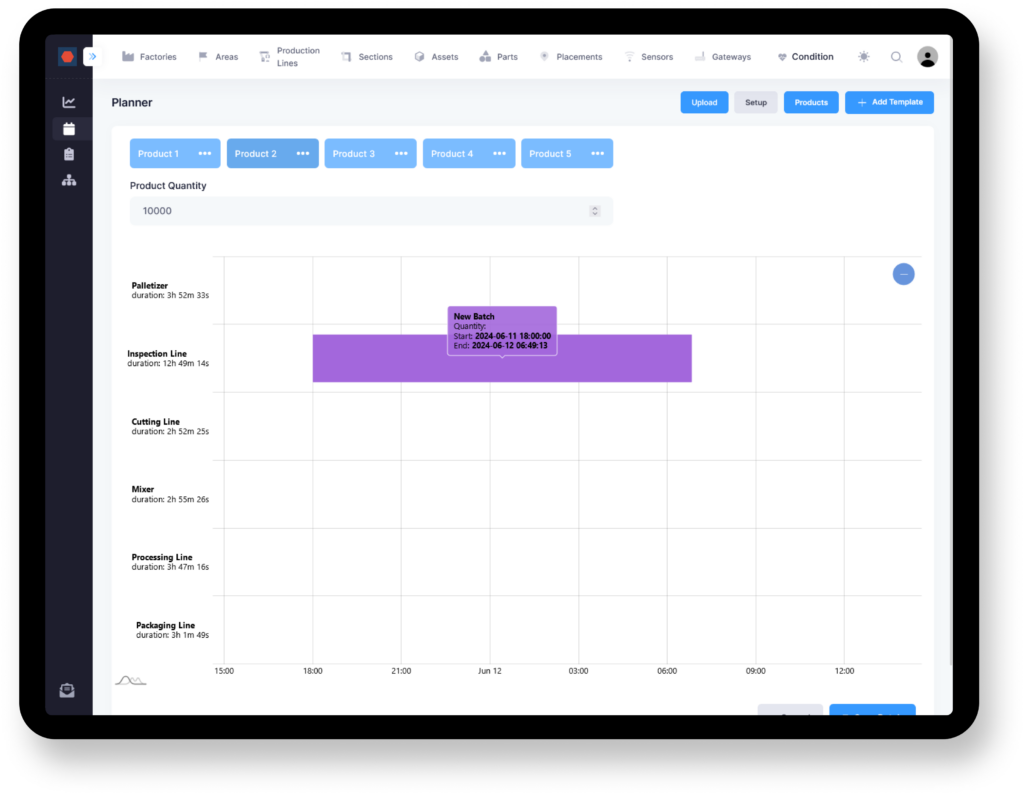

Production Planner

Production Planner

- Optimized Scheduling: Streamline production workflows with flexible scheduling that aligns with resource availability.

- Real-Time Adjustments: Adapt new plans dynamically based on live operational data, ensuring optimal productivity and efficiency.

- Staying on Target: Help teams meet production targets through clear communication of daily goals and expectations.

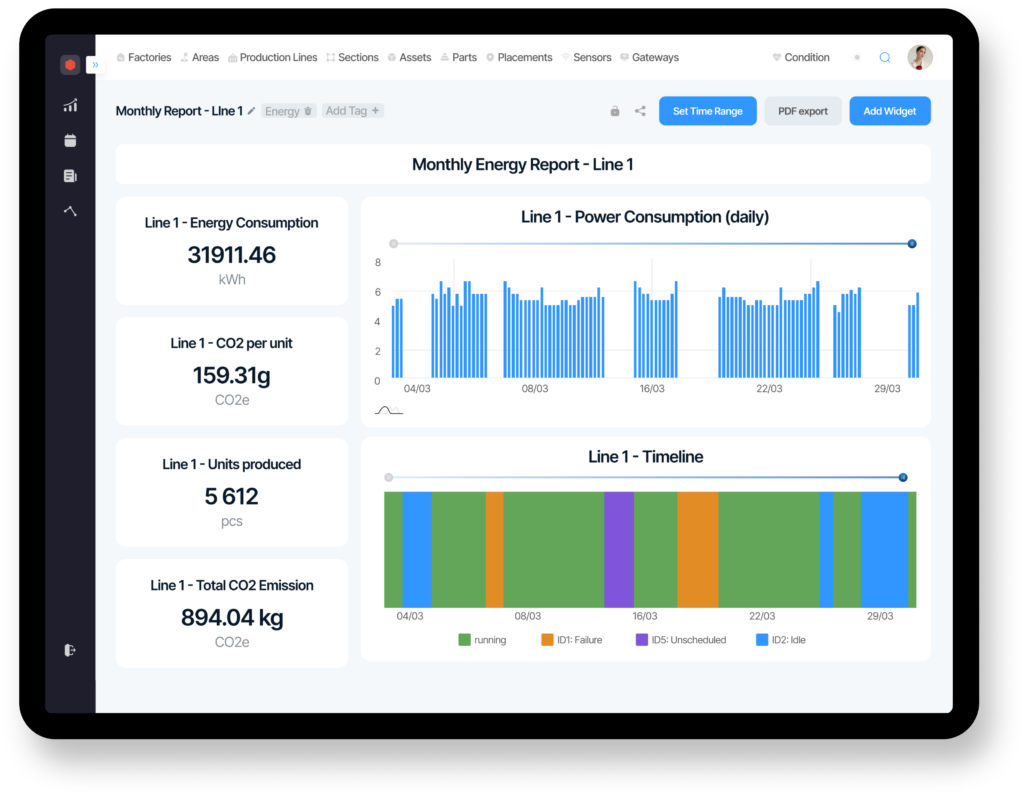

Analysis for OEE

Analysis for OEE

- Deep Insights: Use advanced analytics to dive into efficiency metrics and their related data, uncovering previously hidden opportunities for improvement.

- Trend Analysis: Track performance trends over time to predict potential issues and adjust processes preemptively.

- Root Cause Identification: Pinpoint the exact causes of inefficiencies to effectively target your corrective actions to eliminate issues.

- Performance Optimization: Use data-driven insights to refine operations, boost OEE scores, and enhance overall productivity and employee satisfaction.

Data Collection

Data Collection

- Automated Collection: Capture operational data automatically using plug-and-play hardware, or integrate into existing systems to avoid manual entry errors.

- Real-Time Monitoring: Install sensors to track machine activity and production stops instantly, feeding accurate data for OEE analysis.

- Uploading or synchronizing production data periodically is also possible.

- Event Logging: Equip operators with easy-to-use interfaces to log events quickly, ensuring detailed and precise enrichment of the collected data.

ROI Calculation

Visualize the economics of implementing an OEE system

OEE increase: 0%

Production Capacity Increase: 0%

Production Increase (units): 0

Total Profit Increase: 0