Advance Your Asset Management with Hexastate

Industry-leading automatic vibration analysis to predict equipment issues and increase uptime.

Solution Overview

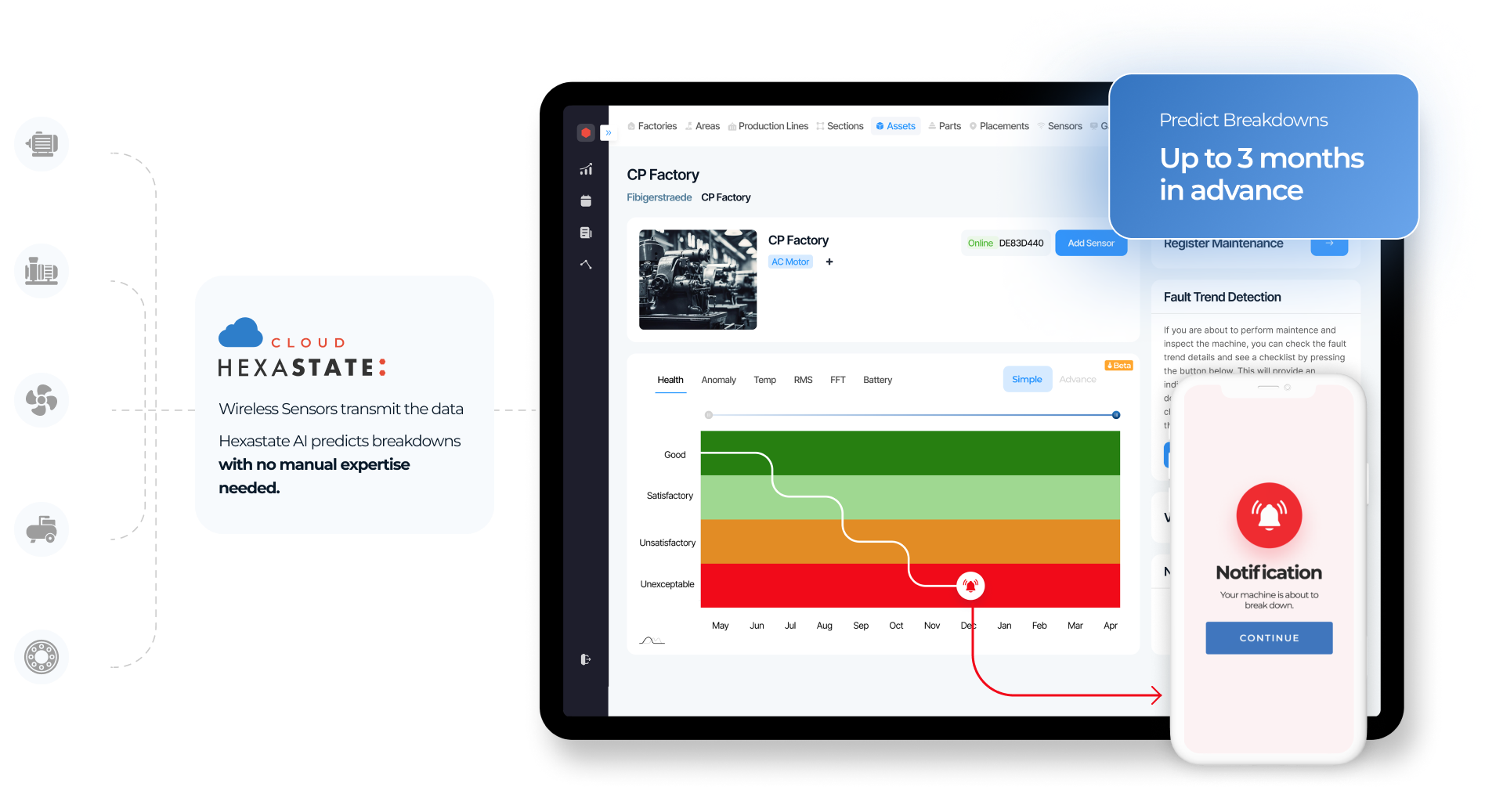

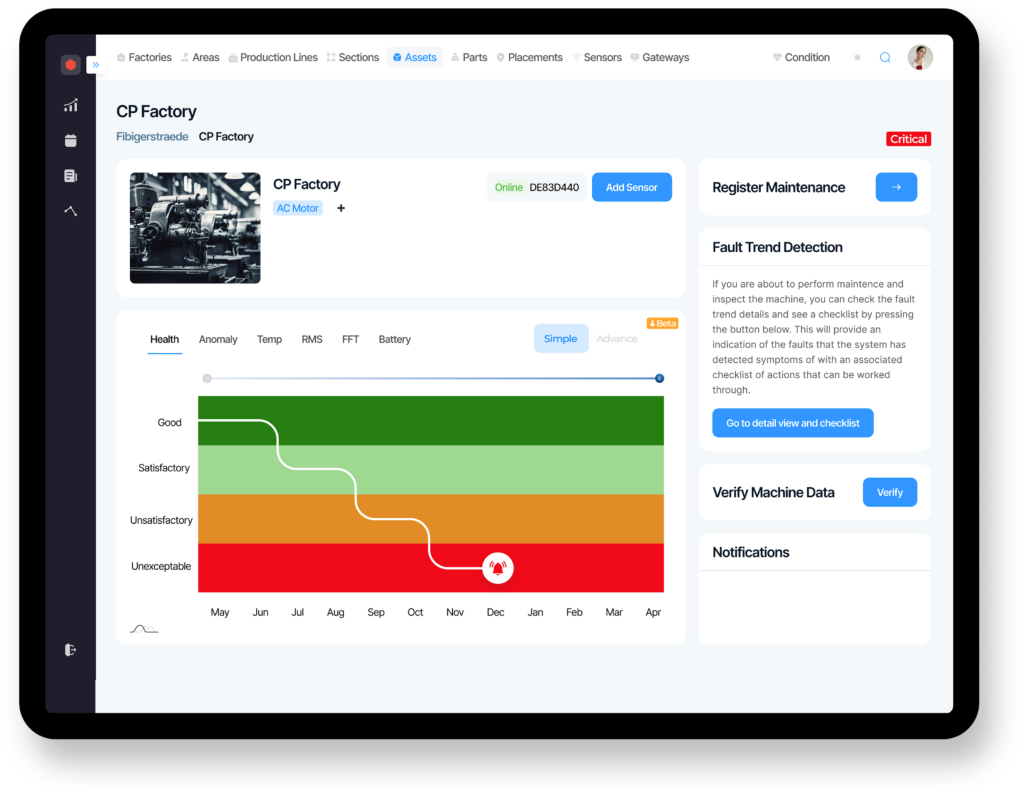

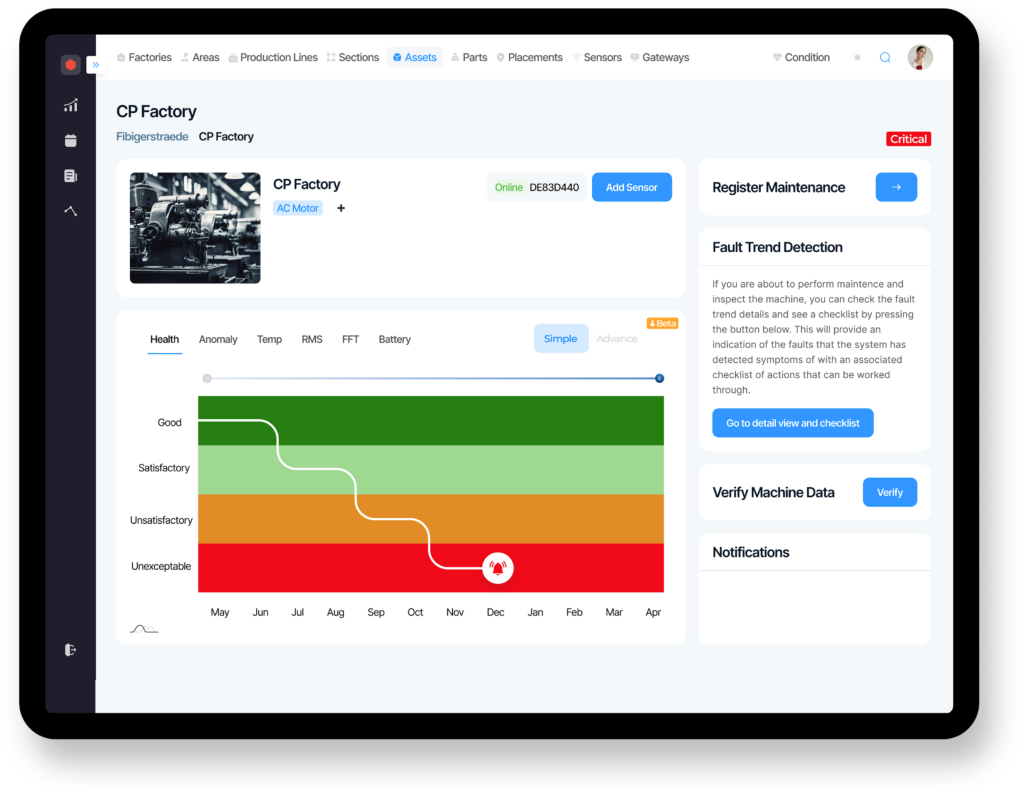

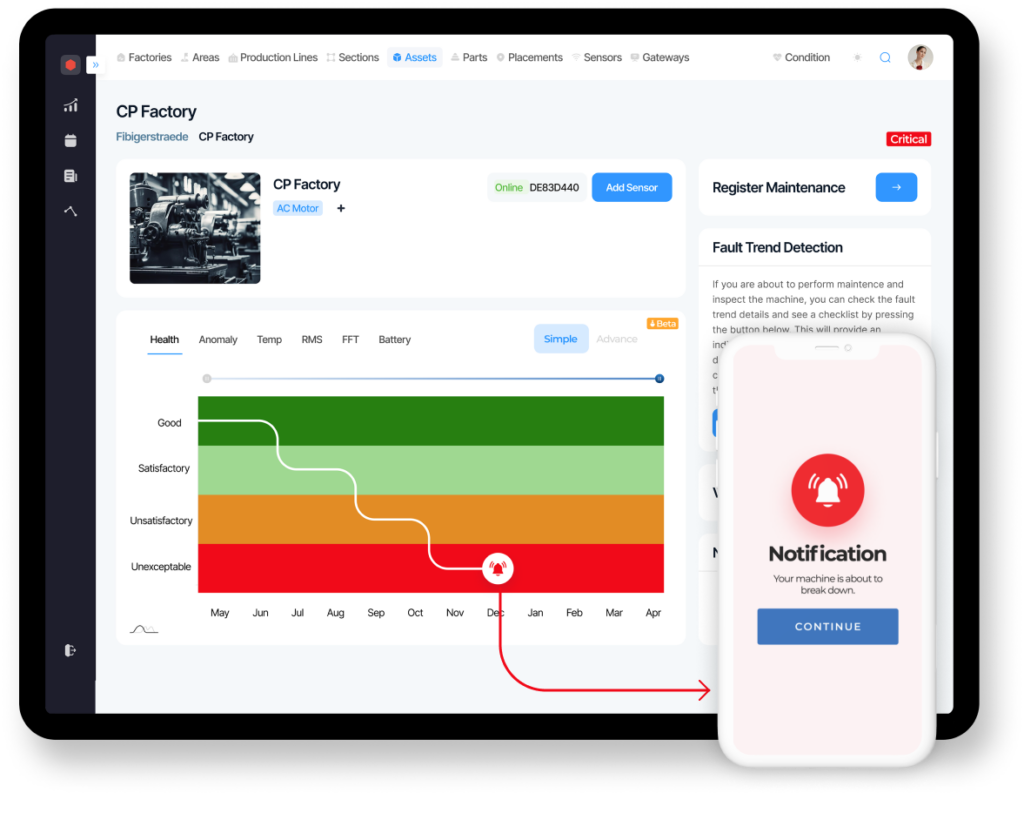

Machine Health

Get alarms before your equipment breaks down

- The Hexastate Health AI-driven algorithm automatically estimates the health of the machine

- Predicts machine failures up to 3 months in advance using the health algorithm, anomaly algorithm and other data inputs

- Eliminates the need for manual analysis as the software acts as the vibration analysis expert

- Tracks RPM automatically to understand load of machine, track faults accurately and in the end to avoid false positives

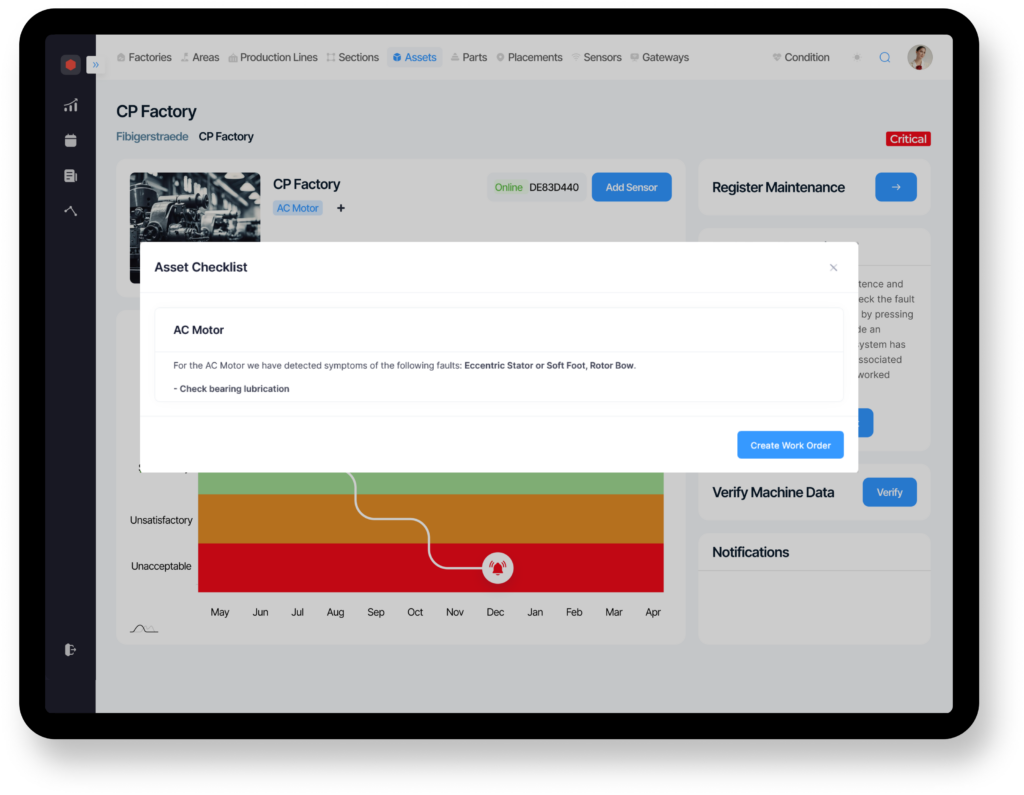

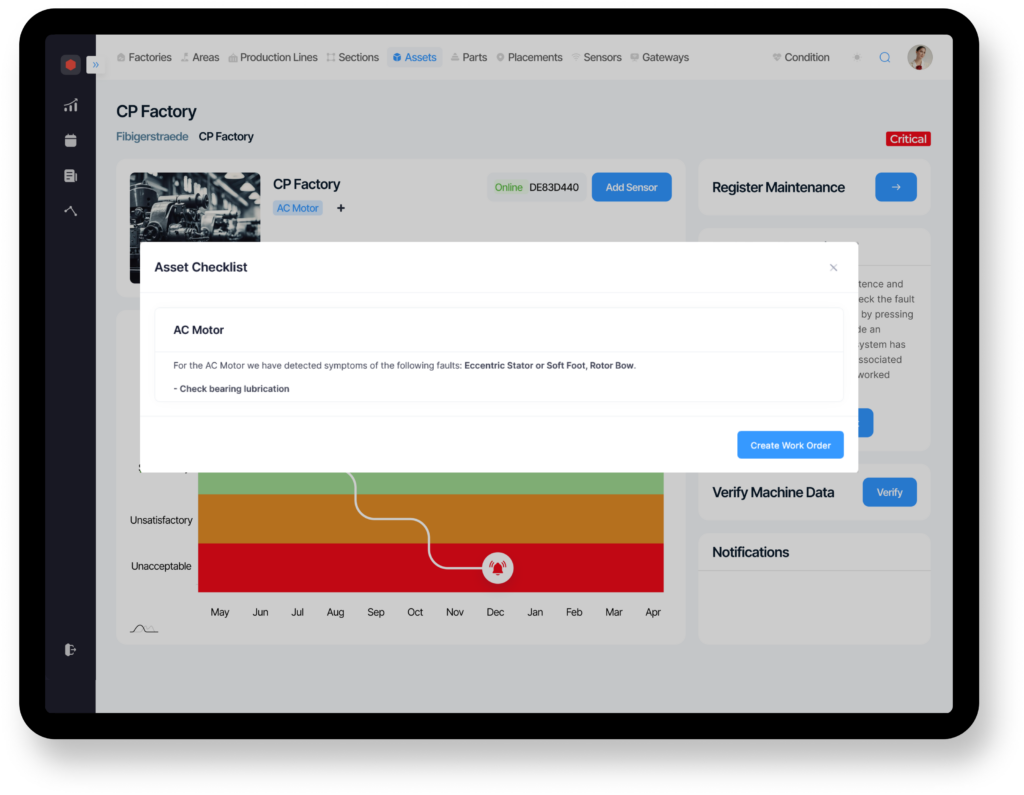

Fault Trends

Fault Trend Checklist

- AI-Driven Fault Detection: Hexastate’s AI analysis automates the detection of fault symptoms, identifying issues like shaft unbalance and bearing wear effortlessly.

- No Manual Analysis: The system automatically pinpoints problems without the need of expertise in vibration analysis.

- Actionable Insights: Transforms the detected faults into checklists for taking appropriate action to the faults, and can generate work orders both in Hexastate and your CMMS if configured.

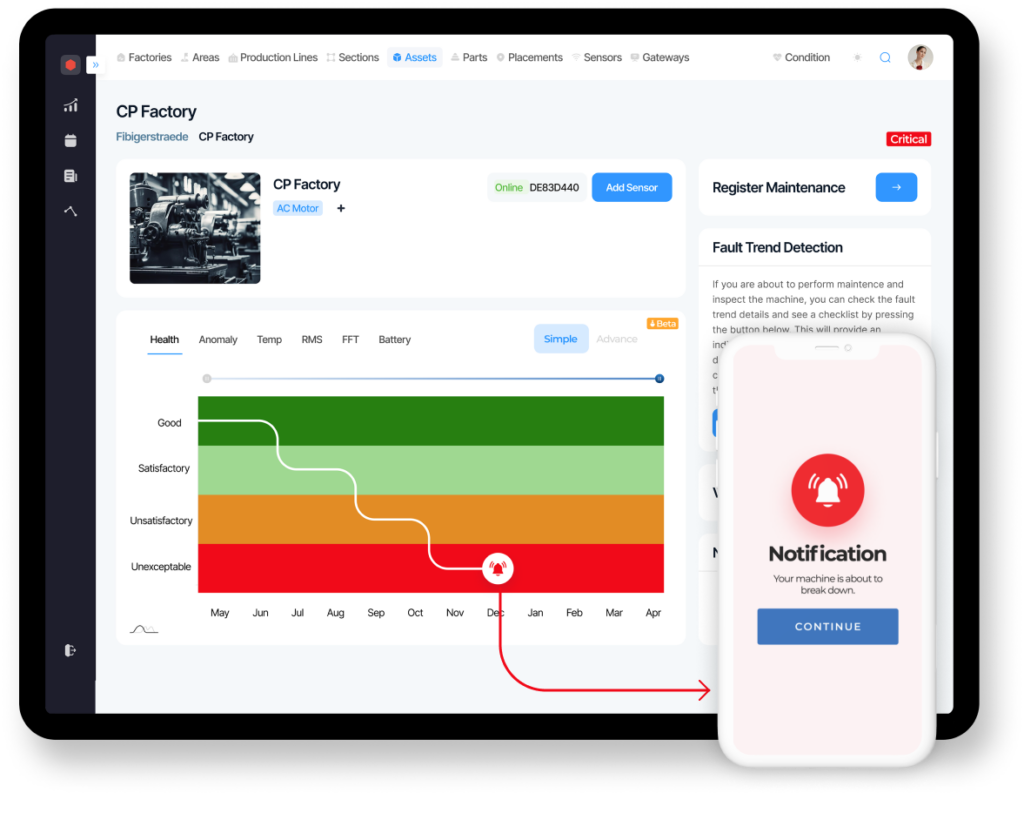

Alarms

Alarms (SMS, Email or in CMMS)

- Direct Notifications: Receive SMS or email alerts directly, ensuring you’re promptly informed of critical updates.

- Fully Customizable: Set custom parameters for the alarms, including cooldowns, custom messages and different triggers.

- CMMS Integration: Seamlessly integrate alarms with Hexastate’s CMMS or your existing solution for data-driven maintenance.

- Alarm Routing: Configure alarms to your preferred destination such as ERP-, MES- and SCADA systems.

Hardware

Vibration Hardware

- Easy Setup: Simply plug the Gateway into a power source and attach the wireless sensors to your asset in less than 5 minutes.

- Effortlessly Connect: Once installed, the sensors automatically connect to the gateway, enabling real-time monitoring and data streaming.

- Convenient Access to data: Access the data anywhere, anytime using the optimized web and mobile interface.

- Reliable Connectivity: The sensors create a self-optimizing mesh network through Wirepas mesh technology, making transmission of data over long distances or even obstructed environments possible.

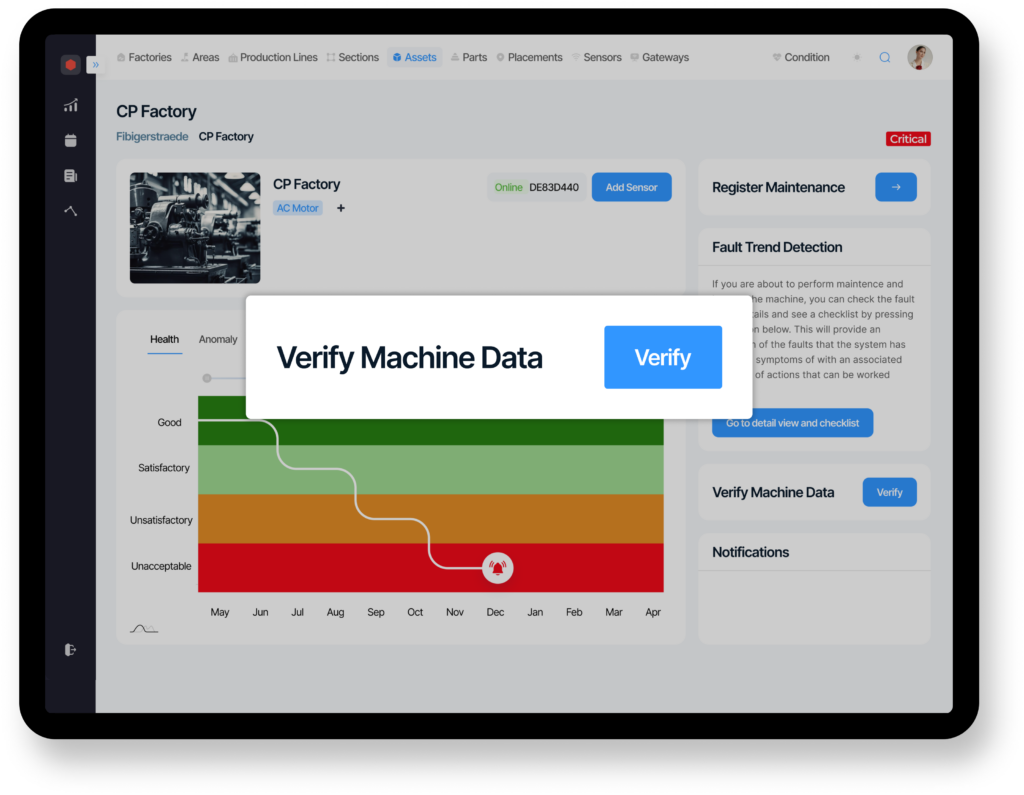

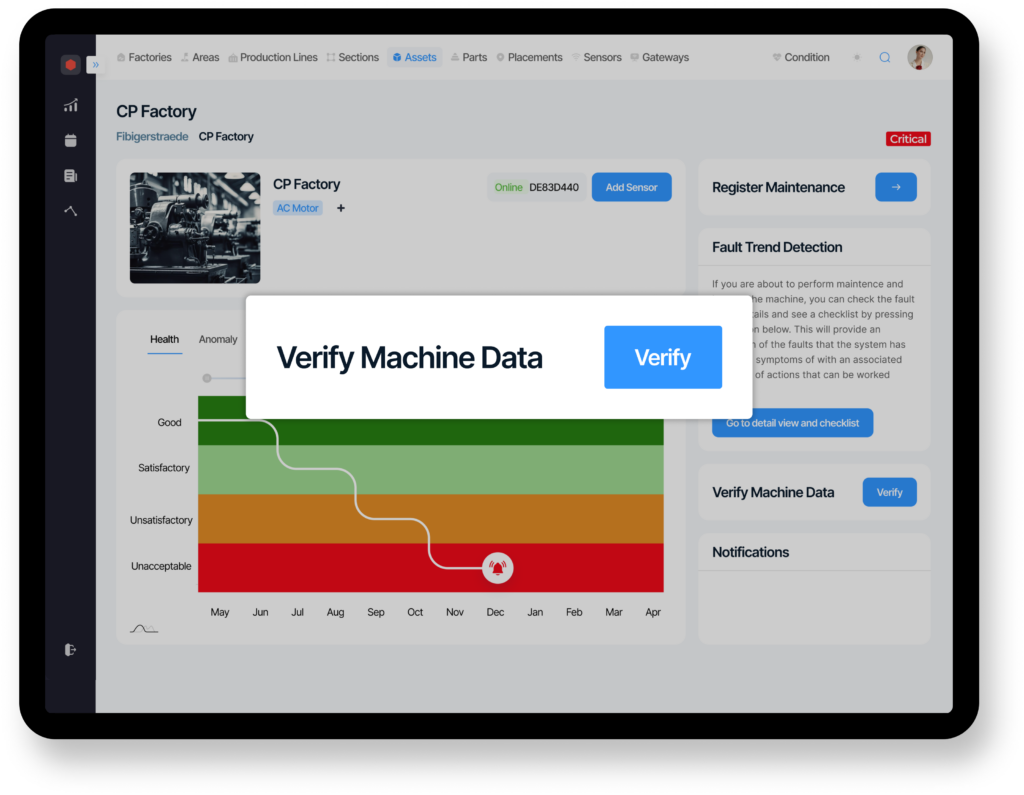

Verify Machine Data

Data Verification Service

- Machine Data Verification Service: Hexastate offers specialized support for verifying machine data, assisting with changes in health or related concerns.

- Expert Analysis: The Hexastate Support team provides detailed feedback on data analysis, sensor installation, and other factors affecting health estimates.

- Verify Condition: Through this feature, Hexastate can provide insights into a condition change if there are doubts, or if the system doesn't indicate specific faults.

- Learn More: Contact our sales team for in-depth information about how this feature can benefit your operations.

Retrofit

What type of machines do Hexastate monitor?

- Pumps: Specializing in the health of rotating machinery, our solutions monitor pumps for optimal performance. Learn more.

- Electric Motors: We keep a vigilant eye on electric motors to prevent downtime and enhance efficiency. Learn more.

- HVAC Systems: Our technology ensures HVAC systems operate smoothly with minimal breakdowns. Learn more.

- Bearings: Bearings are crucial for machine operation; we monitor their health to avoid failures. Learn more.

- Compressors/Chillers: Critical for cooling, we help compressors and chillers run without interruption. Learn more.

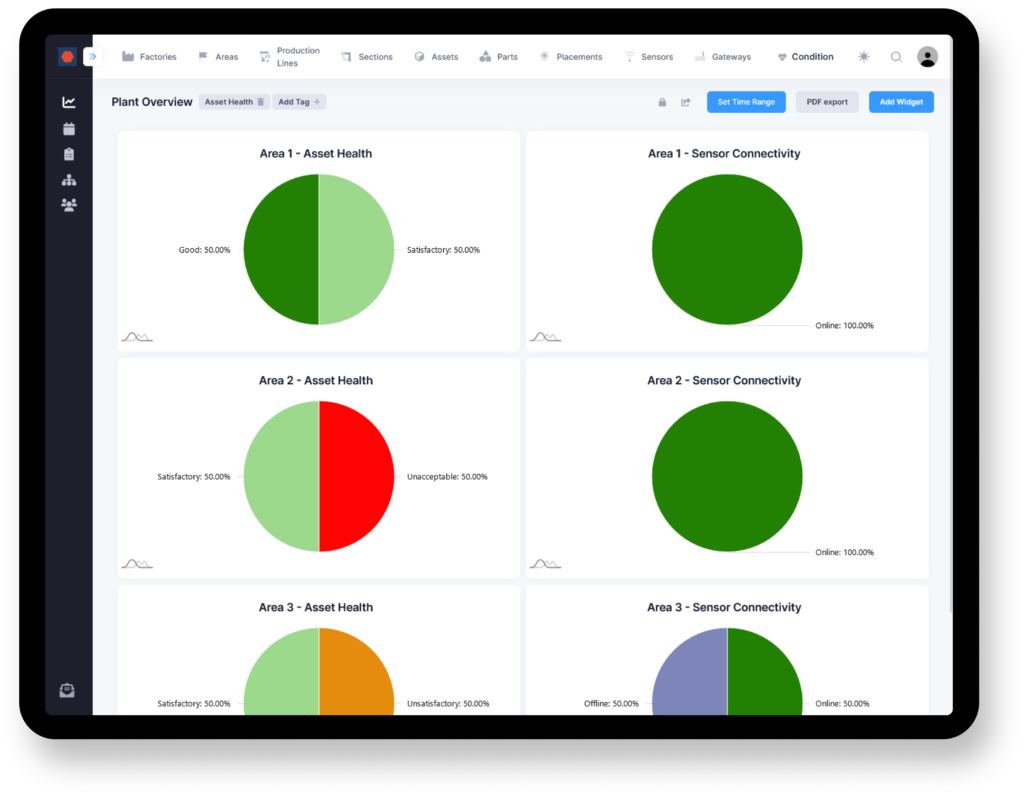

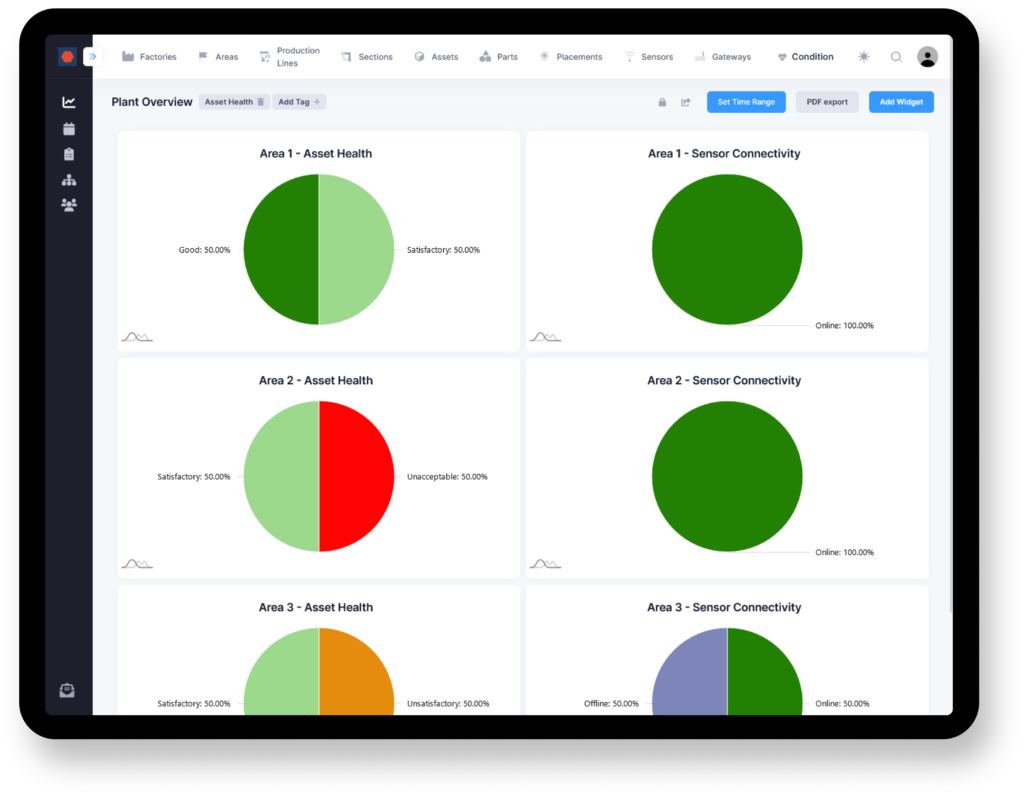

Overview of Plant

Get the full plant overview

- Asset Management: Gain a complete overview of all assets, sensors and more, ensuring insights and proper management of your entire facility.

- Connectivity Monitoring: Obtain a detailed overview of sensor and gateway connections, enabling efficient management of your IoT infrastructure

- Live Tracking: Watch your plant’s performance live, as it happens. Easy-to-grasp charts and graphs show you what’s happening now, helping you make quick yet informed decisions.

Your new toolbox

- Energy Optimization (EO)

- Front Page (FP)

- Production Optimization (PO)

- Globals (GBS)

- Machine Health (MH)

- Maintenance Planner (MP)

- Machine Health

- Energy Overview

- Work Order

- Condition Monitoring

- Analytics

- Fault Trends

- Preventive

- OEE

- ESG

- Alarms

- Easy Overview

- Energy Monitoring

- Hardware

- Maintenance

- Financial Understanding

- Log of history

- Dashboards

- Alarms

- Verify Machine Data

- Inventory

- Integrations

- Hardware

- Retrofit

- Maintenance Stats

- Dashboard Builder

- Overview of Plant

- Integration

- Understanding Uptime

- Dashboards

- Automations

- User Management

- Reports

- App Center

- API and Integrations

- Template Center

- OEE Dashboards

- Event Registration

- Management

- Operators

- Production Planner

- Analysis for OEE

- Alarms

- Data Collection

- MP: Dashboard Builder

Machine Health

Get alarms before your equipment breaks down

- The Hexastate Health AI-driven algorithm automatically estimates the health of the machine

- Predicts machine failures up to 3 months in advance using the health algorithm, anomaly algorithm and other data inputs

- Eliminates the need for manual analysis as the software acts as the vibration analysis expert

- Tracks RPM automatically to understand load of machine, track faults accurately and in the end to avoid false positives

Fault Trends

Fault Trend Checklist

- AI-Driven Fault Detection: Hexastate’s AI analysis automates the detection of fault symptoms, identifying issues like shaft unbalance and bearing wear effortlessly.

- No Manual Analysis: The system automatically pinpoints problems without the need of expertise in vibration analysis.

- Actionable Insights: Transforms the detected faults into checklists for taking appropriate action to the faults, and can generate work orders both in Hexastate and your CMMS if configured.

Alarms

Alarms (SMS, Email or in CMMS)

- Direct Notifications: Receive SMS or email alerts directly, ensuring you’re promptly informed of critical updates.

- Fully Customizable: Set custom parameters for the alarms, including cooldowns, custom messages and different triggers.

- CMMS Integration: Seamlessly integrate alarms with Hexastate’s CMMS or your existing solution for data-driven maintenance.

- Alarm Routing: Configure alarms to your preferred destination such as ERP-, MES- and SCADA systems.

Hardware

Vibration Hardware

- Easy Setup: Simply plug the Gateway into a power source and attach the wireless sensors to your asset in less than 5 minutes.

- Effortlessly Connect: Once installed, the sensors automatically connect to the gateway, enabling real-time monitoring and data streaming.

- Convenient Access to data: Access the data anywhere, anytime using the optimized web and mobile interface.

- Reliable Connectivity: The sensors create a self-optimizing mesh network through Wirepas mesh technology, making transmission of data over long distances or even obstructed environments possible.

Verify Machine Data

Data Verification Service

- Machine Data Verification Service: Hexastate offers specialized support for verifying machine data, assisting with changes in health or related concerns.

- Expert Analysis: The Hexastate Support team provides detailed feedback on data analysis, sensor installation, and other factors affecting health estimates.

- Verify Condition: Through this feature, Hexastate can provide insights into a condition change if there are doubts, or if the system doesn't indicate specific faults.

- Learn More: Contact our sales team for in-depth information about how this feature can benefit your operations.

Retrofit

What type of machines do Hexastate monitor?

- Pumps: Specializing in the health of rotating machinery, our solutions monitor pumps for optimal performance. Learn more.

- Electric Motors: We keep a vigilant eye on electric motors to prevent downtime and enhance efficiency. Learn more.

- HVAC Systems: Our technology ensures HVAC systems operate smoothly with minimal breakdowns. Learn more.

- Bearings: Bearings are crucial for machine operation; we monitor their health to avoid failures. Learn more.

- Compressors/Chillers: Critical for cooling, we help compressors and chillers run without interruption. Learn more.

Overview of Plant

Get the full plant overview

- Asset Management: Gain a complete overview of all assets, sensors and more, ensuring insights and proper management of your entire facility.

- Connectivity Monitoring: Obtain a detailed overview of sensor and gateway connections, enabling efficient management of your IoT infrastructure

- Live Tracking: Watch your plant’s performance live, as it happens. Easy-to-grasp charts and graphs show you what’s happening now, helping you make quick yet informed decisions.

Machine Health Webinar

Watch a short, 20-minute webinar about the machine health solution to learn more!

The webinar goes through the following subjects:

- An introduction to Hexastate and our core mission.

- Introduction to vibration analysis and condition monitoring.

- How machine faults are identified, and how this is represented.

- How to utilize the solution for preventing production breakdowns

ROI Calculation

Visualize the economics of an AI-driven predictive maintenance solution.

Total savings on downtime alone 600000 €

Total savings on energy by running machines in good health80000 €

Total savings on maintenance hours40000 €

Cost savings total720000 €